Heavy-duty CNC lathes play a vital role in shipbuilding, which is mainly reflected in the following aspects:

1. High-precision processing to ensure ship performance

A. Propeller manufacturing:

a) High-precision requirements: As an important power unit of a ship, the accuracy of its geometric dimensions and surface quality is crucial to the operating efficiency and performance of the ship. The heavy-duty CNC lathe is equipped with a precise control system, which can achieve precise control of parameters such as tool path, cutting speed, feed rate, etc., to ensure that all parts of the propeller can achieve extremely high processing accuracy.

b) Low-roughness surface: By optimizing cutting parameters, selecting suitable tools and adopting advanced processing strategies, heavy-duty CNC lathes can maintain a low surface roughness during processing. This smooth and flat surface not only improves the hydrodynamic performance of the propeller, but also reduces the scouring and wear of the propeller by the water flow, extending its service life.

B. Hull structure processing:

a) High-precision requirements: Hull structure parts are an important part of the ship, and their processing accuracy directly affects the overall performance and safety of the ship. Heavy-duty CNC lathes can perform automated processing according to design drawings, ensuring the processing accuracy of hull structural parts and meeting the high standards of shipbuilding.

2. Powerful processing capabilities to cope with large workpieces

A. Processing of large workpieces:

a) Large marine propellers: The diameter of propellers can often reach several meters, which are large and heavy workpieces. Heavy-duty CNC lathes can achieve stable processing of large workpieces with their powerful spindle power, stable machine tool structure and high-precision transmission system.

b) Other large marine parts: In shipbuilding, there are many other large parts that require high-precision processing, such as marine engine cylinders, large flanges, heavy shafts and pipes. Heavy-duty CNC lathes can also meet the processing needs of these parts.

B. Improve production efficiency:

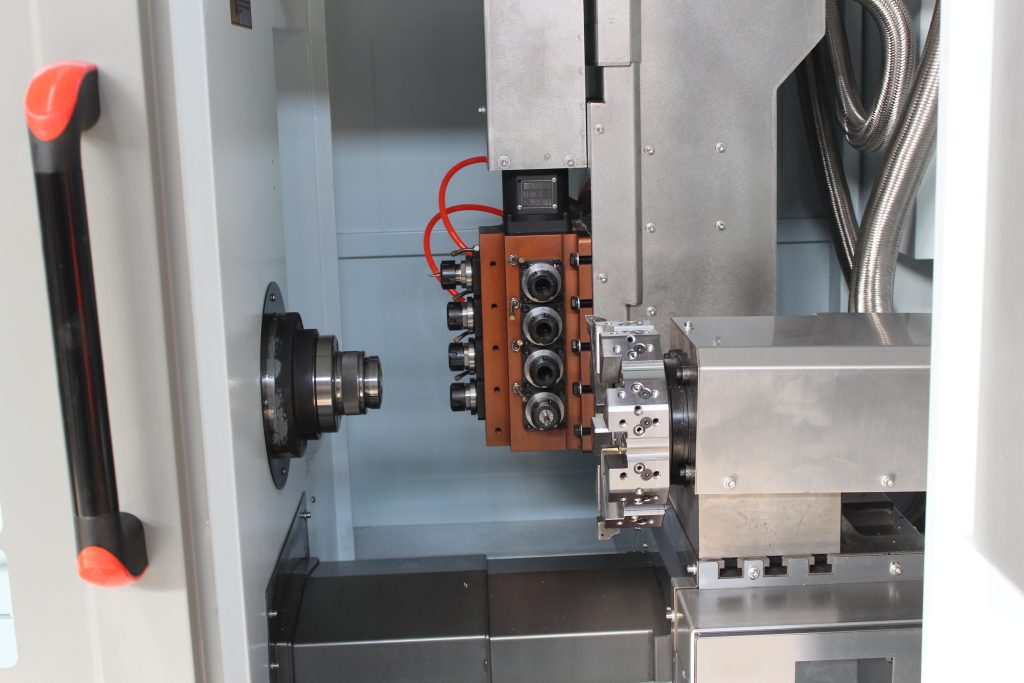

a) Automatic tool changing system: Heavy-duty CNC lathes are equipped with tool libraries and automatic tool changing systems, which can greatly improve processing efficiency and shorten production cycles.

b) Continuous processing capabilities: Through CNC technology, lathes can achieve automated production, continuous processing and multi-process composite processing, further improving production efficiency.

3. Strong adaptability to meet diverse needs

A. Multi-variety processing:

a) Different materials and shapes: There are many kinds of materials and shapes used in shipbuilding. Heavy-duty CNC lathes have a wide range of processing performance and can process straight cylinders, oblique cylinders, arcs and various threads, etc., which can adapt to the processing needs of workpieces of different materials and shapes.

B. Customized services:

a) Flexible adjustment of processing parameters: The control system of heavy-duty CNC lathes can flexibly adjust processing parameters to meet the customized needs of different customers.

b) Rapid response to market changes: With the continuous advancement of shipbuilding technology and the continuous development of the market, the requirements of shipbuilding companies for processing equipment are also constantly increasing. Heavy-duty CNC lathes, with their strong processing capabilities and flexibility, can quickly respond to market changes and meet the diversified needs of shipbuilding companies.

4. Enhance the competitiveness of shipbuilding

A. Improve product quality:

a) Stable processing accuracy: Heavy-duty CNC lathes achieve automated processing through CNC technology, ensuring the stability and consistency of processing accuracy and improving the overall quality of ship products.

b) Reduce scrap rate: High-precision machining and low-roughness surface reduce scrap rate and reduce production costs.

B. Promote industrial upgrading:

a) Promote technological innovation: The application of heavy-duty CNC lathes has promoted the innovation and development of shipbuilding technology and improved the technical level and competitiveness of shipbuilding enterprises.

b) Realize intelligent manufacturing: As one of the key equipment for intelligent manufacturing, the application of heavy-duty CNC lathes in shipbuilding helps to realize the intelligence and automation of shipbuilding.

In summary, heavy-duty CNC lathes play a vital role in shipbuilding. Their high-precision machining, strong machining capabilities, and strong adaptability provide a strong guarantee for shipbuilding. With the continuous advancement of technology and the continuous development of the market, heavy-duty CNC lathes will play a more important role in shipbuilding.