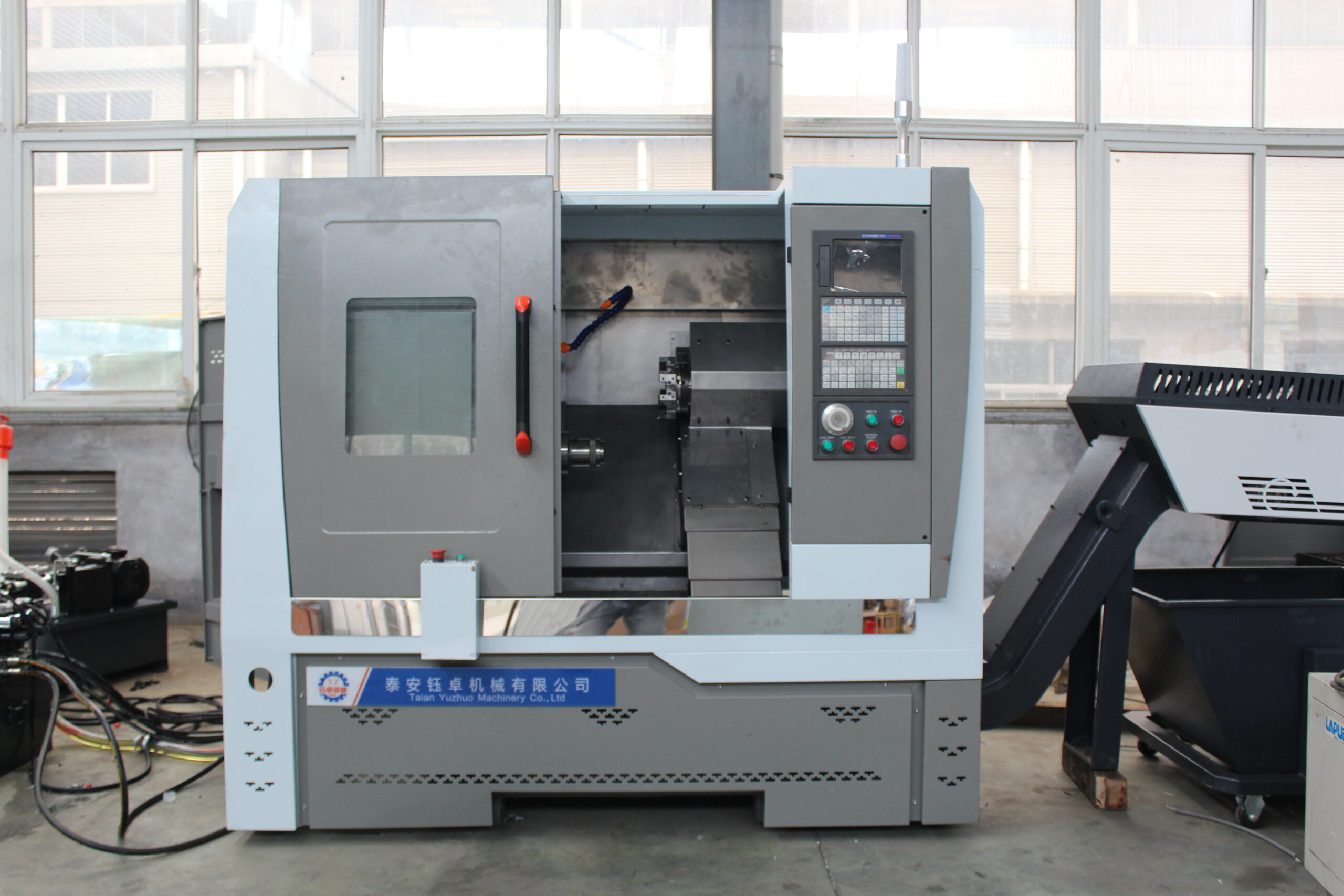

In the field of modern mechanical processing, inclined bed CNC lathes have been widely used for their high-precision and high-efficiency processing performance. Among them, precise control of the power turret and Y-axis is the key to achieving efficient and high-quality processing on inclined bed CNC lathes. This article will deeply explore the precise control techniques of the power turret and Y-axis in the operation of inclined bed CNC lathes, helping readers better master the operation essentials of this advanced processing equipment.

-

Power tool turret operating skills

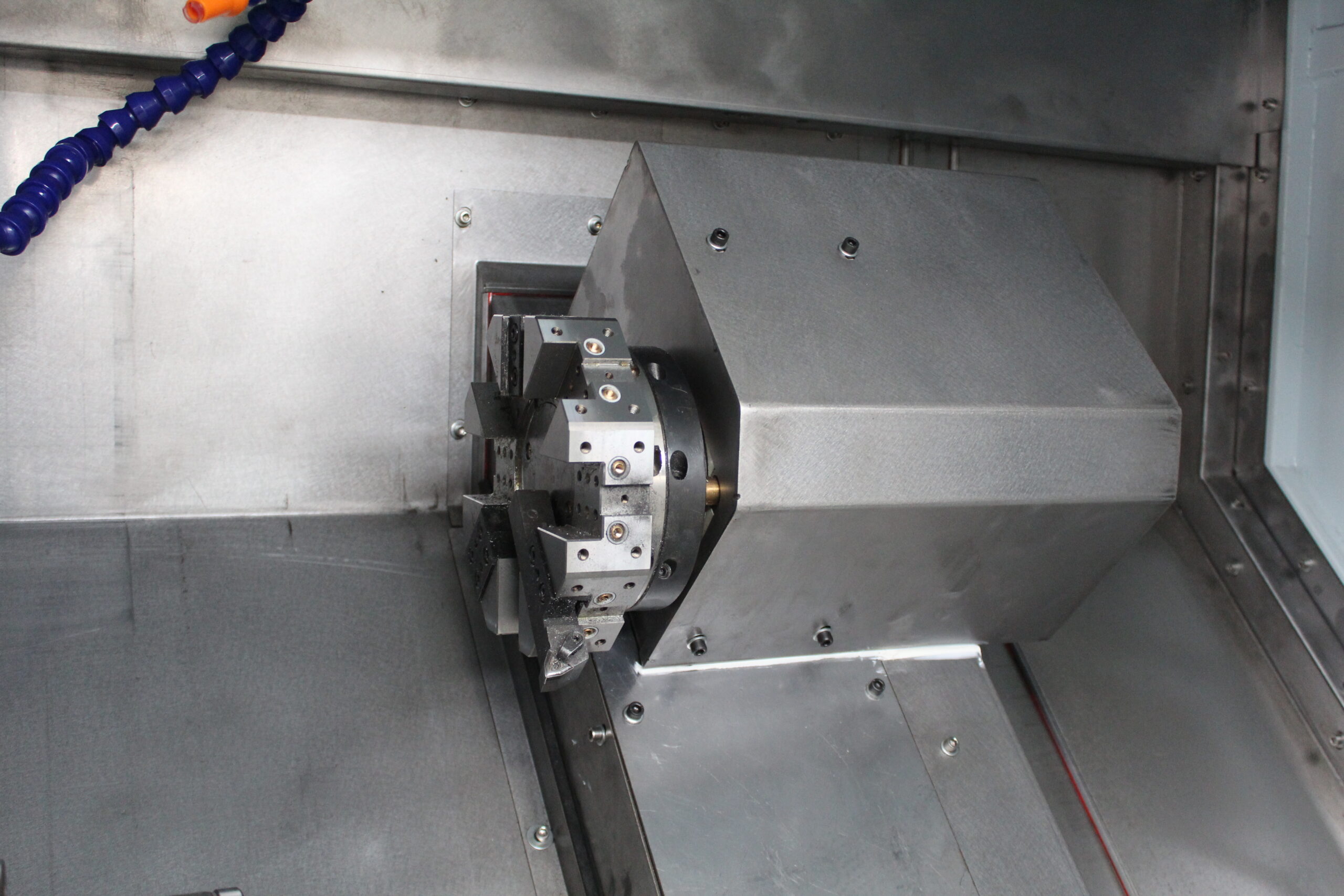

As an important part of the inclined bed CNC lathe, the power turret directly affects the processing quality and efficiency. During the operation, you need to pay attention to the following tips:

Reasonable selection of tools: According to the processing materials and process requirements, select appropriate tool types and specifications to ensure the matching of the tool and the workpiece, reduce cutting force, and improve processing accuracy.

Accurate tool setting: During the tool setting process, it is necessary to ensure that the positions of the tool and the workpiece are accurate. Use the tool setting function of the CNC system to perform precise tool setting operations to avoid collision and interference between the tool and the workpiece.

Optimize cutting parameters: According to the characteristics of the processing material and tool, parameters such as cutting speed, feed amount and cutting depth should be reasonably set to ensure the stability and efficiency of the cutting process.

-

Y-axis precise control skills

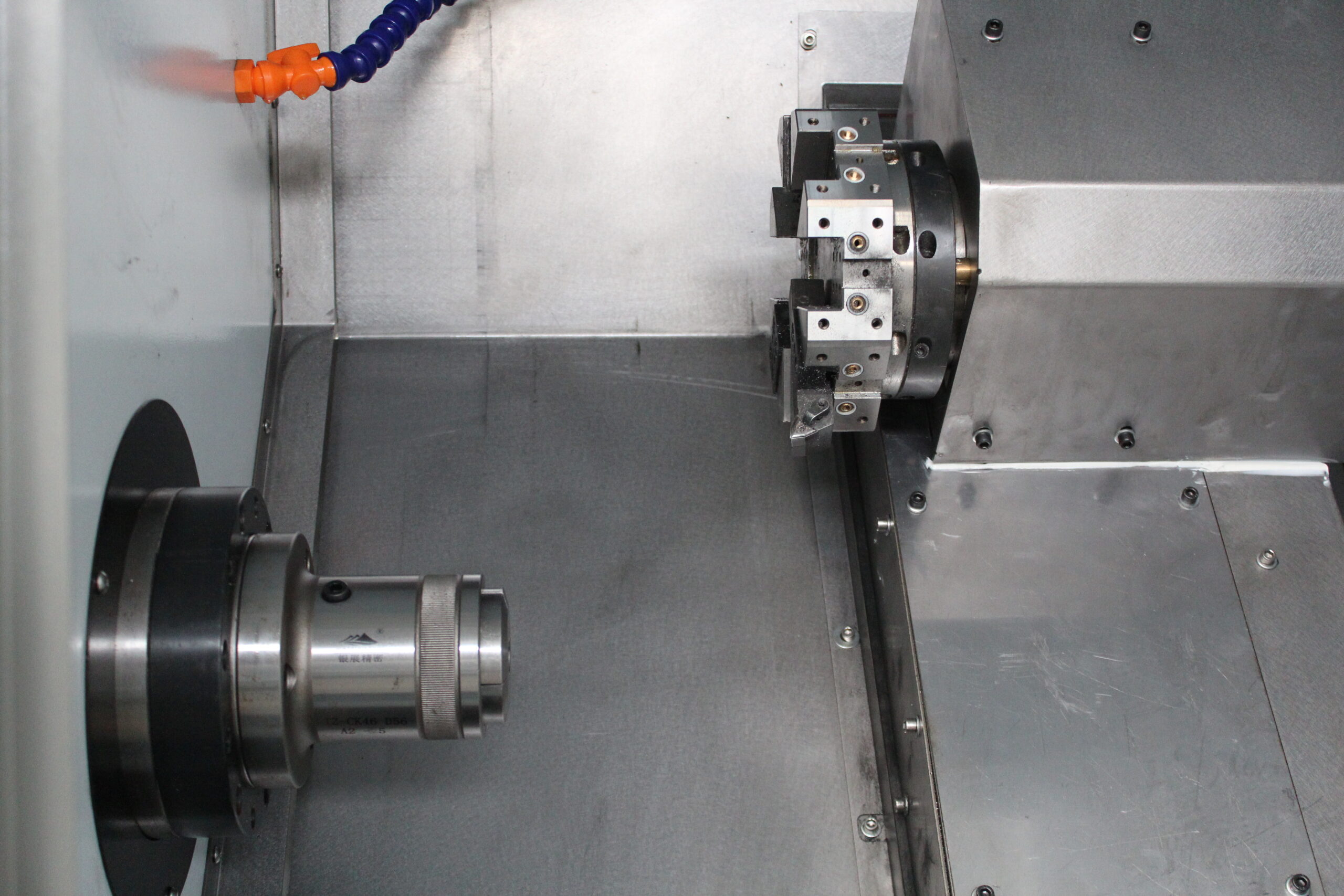

As one of the key motion axes of the inclined bed CNC lathe, the Y-axis’ precise control is crucial to ensure machining accuracy. Here are some tips for precise Y-axis control:

Regular calibration: Calibrate the Y-axis regularly to ensure its synchronization and accuracy with the CNC system. Use professional calibration tools and methods to accurately adjust the Y-axis and eliminate errors.

Optimize the movement trajectory: According to the processing requirements and workpiece shape, reasonably plan the movement trajectory of the Y-axis. By optimizing the motion trajectory, unnecessary idle strokes and pauses are reduced, and processing efficiency is improved.

Control speed and acceleration: Reasonably set the movement speed and acceleration of the Y-axis to ensure its stability and responsiveness during processing. Avoid vibration and errors caused by excessive speed or excessive acceleration.

-

Cooperative operation of power turret and Y-axis

In the actual operation of inclined bed CNC lathes, the collaborative operation of the power turret and the Y-axis is the key to achieving efficient and high-quality processing. Here are some tips for working together:

Programming optimization: During the programming process, the coordinated action of the power turret and the Y-axis is fully considered. By optimizing cutting paths and tool trajectories, the seamless connection between the two is achieved and processing efficiency is improved.

Real-time monitoring and adjustment: During the processing process, the working status of the power turret and Y-axis is monitored in real time. Once abnormalities or errors are discovered, adjustments and corrections are made in a timely manner to ensure the stability and accuracy of the processing process.

Experience accumulation and sharing: In actual operations, the experience of collaborative operation of the power turret and Y-axis is continuously accumulated and summarized. Continuously improve your own operating level and skills through communication and sharing with other operators.