Mini CNC lathe is a small CNC machine tool suitable for small batch production and teaching scenarios. The following are the selection and operation skills of mini CNC lathe:

1. Selection of mini CNC lathe

A. Brand and manufacturer: Choose well-known brands and reputable manufacturers to ensure the quality and after-sales service of the lathe.

B. Processing capacity: According to the processing requirements, choose a lathe with appropriate processing range, precision and speed. For example, pay attention to the maximum processing diameter, processing length, spindle speed and other parameters of the lathe.

C. Control system: Choose an easy-to-operate and powerful CNC system. Modern CNC systems usually have characteristics such as graphical interface, simple programming, and strong fault diagnosis capabilities.

D. Price and cost-effectiveness: Within the budget, choose a lathe with high cost-effectiveness. Consider factors such as the performance, function, quality and after-sales service of the lathe, and comprehensively evaluate its cost-effectiveness.

E. After-sales service: Understand the manufacturer’s after-sales service policy, including repair, maintenance, technical support and other aspects. Choose a manufacturer that provides perfect after-sales service to ensure the long-term use of the lathe.

2. Operating skills of mini CNC lathes

A. Programming skills:

a) When programming, you need to consider the processing order of parts, material hardness, and reasonable speed, feed rate and cutting depth selection.

b) For different materials, such as carbon steel, carbide and titanium alloy, appropriate speed, feed rate and cutting depth should be selected.

c) Follow the processing principles of drilling first and then flat end, processing large tolerance first and then processing small tolerance to ensure processing quality and efficiency.

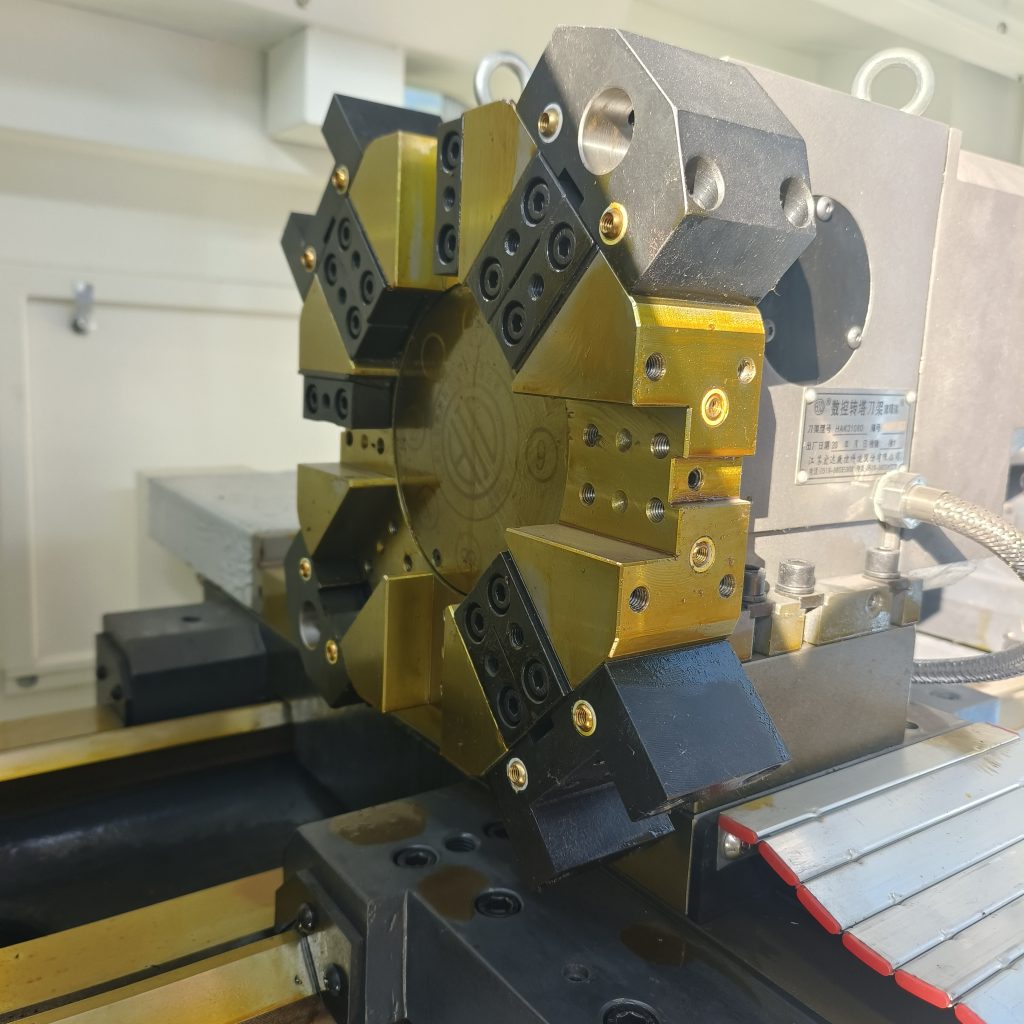

B. Tool setting skills:

a) Select the center of the right end face of the part as the tool setting point and set it as the zero point.

b) After the machine tool returns to the origin, set each tool needed in turn.

c) For tool setting on the Z axis, let the tool touch the right end face and enter Z0 for measurement. The tool compensation value of the tool will automatically record the measured value.

d) For tool setting on the X axis, use the trial cutting method to set the tool by turning the outer circle of the part and measuring the value of the outer circle being turned.

C. Debugging skills:

a) After programming and tool setting are completed, test cutting and debugging are performed to prevent collision accidents caused by program errors or tool setting errors.

b) First perform empty stroke simulation processing, and let the tool move 2 to 3 times the total length of the part to the right in the machine tool coordinate system.

c) After the simulation processing is completed, confirm that the program and tool setting are correct before starting the actual processing.

d) After the first part is processed, self-inspection and full-time inspector inspection are required. Only after confirmation of qualification can mass production be carried out.

D. Preventing machine tool collisions:

a) Machine tool collisions are extremely harmful to machine tool accuracy, and we must be highly vigilant and take measures to prevent them.

b) Pay special attention to the machine tool in the initial stage of executing the program and when changing the tool, to avoid collisions caused by program editing or tool information input errors.

c) Closely observe the machine tool movement, spark generation, noise and abnormal noise, vibration, and burning smell. Once an abnormality is found, the program should be stopped immediately and the problem should be solved before continuing the processing.

E. Precautions during processing:

a) During the processing, be diligent in measuring and checking, and adjust the tool compensation value in time according to the actual situation to ensure the qualified rate of parts.

b) Pay attention to the wear of the tool and adjust the processing parameters in time according to the different processing materials.

In summary, when choosing a mini CNC lathe, factors such as brand, processing capacity, control system, price and after-sales service should be considered; when operating, skills such as programming, tool setting, debugging and preventing machine tool collision should be mastered to ensure processing quality and efficiency.