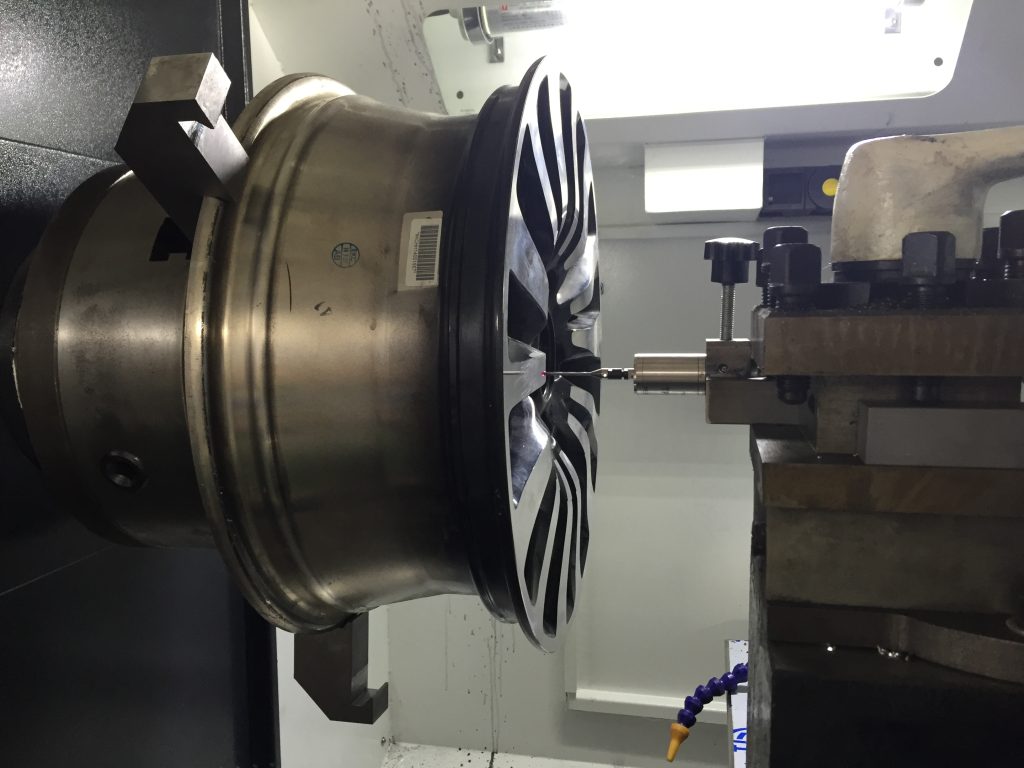

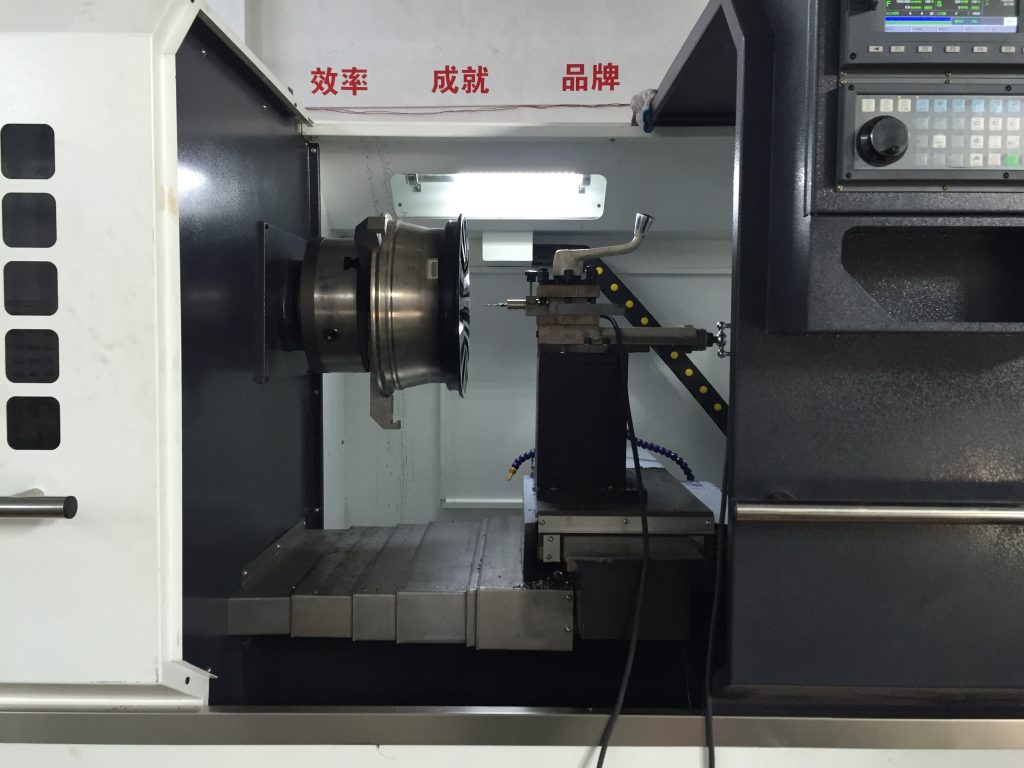

The selection and installation of CNC lathe chucks are crucial to ensure processing accuracy and improve production efficiency. The following is a detailed answer to the selection and installation skills of CNC lathe chucks:

1. Selection of CNC lathe chucks

1) Type selection:

a) Manual clamping chuck: suitable for processing simple workpieces, easy to operate and low cost.

b) Hydraulic pump chuck and gear chuck: suitable for workpieces with high precision requirements, can provide stable clamping force and positioning accuracy.

c) Spring chuck: suitable for certain specific occasions, with automatic clamping or loosening functions.

2) Specification selection:

a) The specifications of the chuck should match the lathe, and the chuck specifications should be selected according to the diameter of the lathe spindle hole and the size of the workpiece. Generally speaking, the larger the diameter of the chuck, the larger the size of the workpiece that can be processed.

b) At the same time, it is also necessary to consider the parameters such as the aperture and clamping range of the chuck to ensure that the workpiece can be clamped and meet the processing requirements.

3) Material selection:

a) Cast iron chuck: high strength, but high density and heavy weight, not suitable for high-speed processing.

b) Steel chuck: good wear resistance, suitable for processing hard material workpieces.

c) Copper alloy chuck: good thermal conductivity, suitable for long-term high-speed processing.

4) Other factors:

a) For processing sites where workpieces are frequently changed, chucks with quick-change devices can be selected to improve production efficiency.

b) Consider whether the chuck’s pressure, precision, rigidity and other parameters meet the processing requirements.

c) Choose chucks from well-known brands to ensure chuck quality and after-sales service.

2. Installation tips for CNC lathe chucks

1) Preparation:

a) Make sure the contact surface of the chuck is clean, free of oil and impurities.

b) Check whether the mating surface of the lathe spindle hole and the chuck is intact, without damage or deformation.

2) Installation steps:

a) Bring the chuck close to the lathe spindle pull rod and screw the chuck to the bottom by hand.

b) Tighten the screws in sequence to fix the chuck. Pay attention to the tightening sequence and strength of the screws to avoid chuck deflection or loosening.

c) Install dust cover to prevent flying chips from entering the chuck and spindle, affecting the processing accuracy and machine life.

3) Debugging and inspection:

a) After installation, perform an idle run test to check whether the chuck runs smoothly and without abnormal noise.

b) Use a dial indicator or micrometer to check the centering accuracy and runout of the chuck to ensure that it meets the processing requirements.

c) If the chuck is found to be deflected, loose or not up to standard, it should be adjusted or replaced in time.

4) Precautions:

a) During installation and use, avoid tightening the screws with too large or too small torque to avoid damaging the chuck or lathe spindle.

b) Check the wear of the chuck regularly and replace the severely worn jaws or chuck in time.

c) Keep the chuck clean and lubricated to extend its service life.

In summary, the selection and installation of CNC lathe chucks need to comprehensively consider multiple factors such as type, specification, material, etc., and follow the correct installation steps and precautions. Through reasonable selection and correct installation, it can ensure that the chuck plays the best performance in the CNC lathe and improve the processing accuracy and production efficiency.