CNC Machining Center China Manufacturer

- CNC system: optional GSK218M / Siemens 808 / Fanuc / Mitsubishi M80 /Syntec 22MA2. Tool magazine: optional funnel type tool magazine with 12/16/20 tool positions, Arm type tool magazine with 16/243.Spindle speed:8000/10000/15000rpm

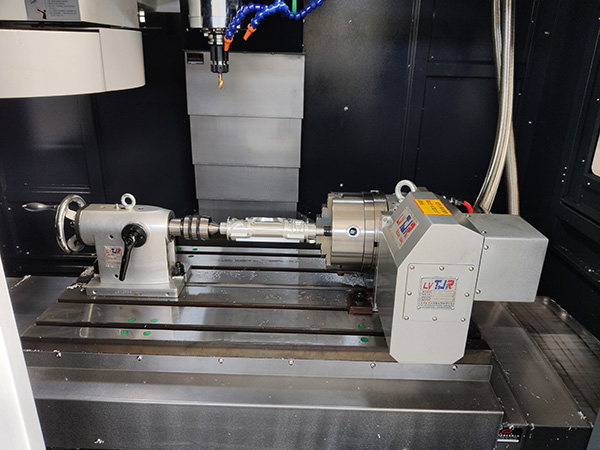

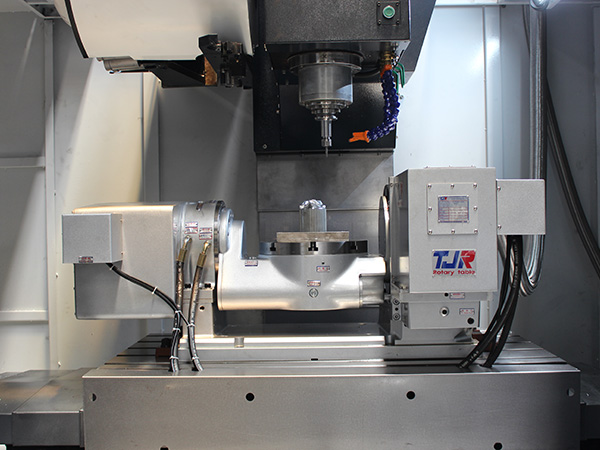

- Turntable: four-axis five-axis

- Coolant through spindle

- Spindle oil cooling

- Chip conveyor

CNC machining center for metal working

The overal framework is made of high grade casting iron with tice heat treatments and magneic resonance. The natural aging relieves intemalstress to ensure the lasting best rigidity and high precision.

The bed base assembling with the long span coumn design increases the contact area between the column and the base.3.Axis assembled with scuare cuide rails, increase the processin stenoth and stock resistance signifcaty. The epoxy resinstick processind and artificiascraping grinding ensure the precision and stability.

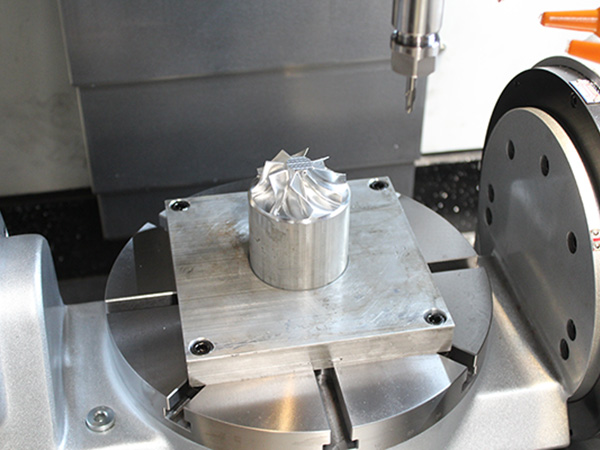

Multi-axis accuracy

Our CNC machining center can be equipped with fourth and fifth axes to achieve multi-angle processing, reduce the number of workpiece clampings, ensure accuracy and improve production efficiency.

Efficient chip removal

Our vertical CNC machining centers are designed with efficient chip evacuation systems to ensure smooth, uninterrupted machining processes. This feature not only improves the quality of the finished part, but also contributes to a cleaner, safer work environment.

Can be customized for various applications

We understand that different industries have unique processing requirements. Our vertical CNC machining centers are highly customizable, allowing you to adapt the machine to your specific application. Whether you are in aerospace, automotive or general manufacturing, our machines are tailor-made to meet your needs.

Strict quality control

Quality is the top priority of our manufacturing process. Every vertical CNC machining center undergoes strict quality control measures to ensure it meets the highest standards. This commitment to quality results in reliable and consistent performance.

Why Choose CNC Machining Center

CNC Machining Center Applications

Aerospace Components

Our vertical CNC machining center is ideal for the aerospace industry, where precision and complex geometries are paramount. Whether it’s milling intricate components for aircraft engines or crafting structural parts, our machines deliver the accuracy required for aerospace applications.

Automotive Parts Manufacturing

In the automotive sector, where efficiency and precision are critical, our vertical CNC machining center shines. It is capable of producing various automotive components, from engine parts to intricate components for advanced safety systems.

Automotive Parts Manufacturing

In the automotive sector, where efficiency and precision are critical, our vertical CNC machining center shines. It is capable of producing various automotive components, from engine parts to intricate components for advanced safety systems.

General Manufacturing and Prototyping

The versatility of our vertical CNC machining center makes it an excellent choice for general manufacturing and prototyping. It can handle a wide range of materials and designs, making it suitable for producing prototypes and custom parts across different industries.

More Information

The spindle assembled with high power servo motor driving,high torque and wide range output.

The major outsourced components are all provided by foreign.

Precision vertical machining center..Using ATC24 manipulator automatic tool change magazine,quick changing tools time reaches

3seconds8.Using original servo motor on 3 axes.Rapid feed speed can reach 48m/min.Motor base contact surface under artificial scraping griding, increase con-tact area and lasting stability of machine.

Using oricinal Taiwan HIWIN OR PM c3 class precision bal screw. Specialized iapanese Nsk bearing with DB fiting method provides strong torcueon machine processing.The bal screw proper pre-stretching treatment after instalation effectively decreases thermal stretch to guarantee feed positionaccuracy and machining stability.

Soindle head desicned wit double enclosed structure and increasing slider assembling base distance, effectively guarantee the machine processino strength.