Standard configuration:

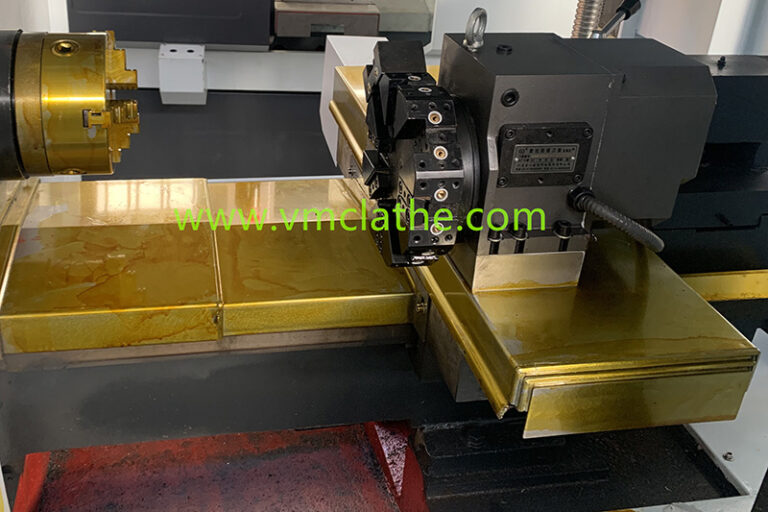

- GSK controller

- Four station electrical tool post or gang type tool post

- collect

- manual tailstock

Optional configuration:

- Fanuc/Siemens/Mitsubishi controller

- Hydraulic chuck and hydraulic tailstock

- chip conveyor

- bar feeder

CK6132 cnc lathe machine for Bearing seat

| ITM | unit | CK6132 |

| Max. Swing over bed | MM | 350 |

| Max. Swing over cross slide | MM | 180 |

| Max. work length | Mm | 400 |

| Max. Z axis Travel | MM | 450 |

| Max. X axis Travel | MM | 280 |

| Spindle bore | MM | 48 |

| Spindle nose | A2-5 | |

| Spindle speed range | RPM | 100-2500 |

| Spindle type | unit | Independent spindle |

| Chuck | MM | Pneumatic chuck/manual 3 jaws 160mm |

| Bed width | MM | 260 |

| x/z fast feed | Mm/min | 6000/8000 |

| x/z cutting travel speed | Mm/min | 1-6000 |

| Number of tool turret | gang type tool post | |

| Tool shank type | MM | 16*16/20*20 |

| Positioning accuracy | MM | X≤0.010 Z ≤0.015 |

| Repeatability Psoitioning accuracy | MM | X≤0.0075 Z ≤0.010 |

| Min. unit set | MM | 0.001 |

| roundness | MM | ≤0.007 |

| Diameter uniformity | MM | ≤0.03 (length 300) |

| Flatness | MM | ≤0.02 (Diameter 300) |

| Surface Roughness (Steel) | Ra1.6um | |

| Dia. of tailstock sleeve | MM | 60 |

| Tailstock sleeve taper | MT4 | |

| Max. Tailstock sleeve travel | MM | 100 |

| Spindle drive motor power | KW | 4 |

| Coolant pump power | W | 90 |

| size | MM | 2050X1500X1650 |

| weight | 1.2T |

Choosing a CNC lathe for metal processing is a decision-making process that requires comprehensive consideration of many factors. The following is a practical guide to help you choose the right equipment according to your actual needs. 1. Clarify processing needs and goals a) Processing materials Determine the type of metal material (such as steel, aluminum, […]

When choosing a CNC lathe suitable for mass production, you need to focus on the equipment’s production efficiency, stability, degree of automation and long-term maintenance costs. Here are some key factors and suggestions to help you make a wise choice: ________________________________________ 1. Production efficiency (1) Spindle speed and power A. High speed: Choose a lathe […]

When purchasing a CNC lathe, you need to focus on the following technical parameters to ensure that the equipment can meet the processing requirements and has a high cost-effectiveness: 1. Machine tool specifications (1) Processing range Maximum processing diameter: determines the maximum workpiece diameter that the machine tool can handle. Maximum processing length: determines the […]

Flat-bed CNC lathe and vertical CNC lathe have significant differences in structure, function, application scenarios, etc. The following is a detailed comparison and selection suggestions between the two: Difference 1. Structural characteristics A. Flat-bed CNC lathe: Its bed design is relatively flat, which helps to provide stable support and ensure accuracy and stability during processing. […]

Mini CNC lathe is a small CNC machine tool suitable for small batch production and teaching scenarios. The following are the selection and operation skills of mini CNC lathe: 1. Selection of mini CNC lathe A. Brand and manufacturer: Choose well-known brands and reputable manufacturers to ensure the quality and after-sales service of the lathe. […]

Application examples of flat bed CNC lathes in complex parts processing can be summarized into the following key steps and specific details: 1. Part analysis A. Part type: complex parts, such as shaft parts, sleeve parts, etc., which may contain multiple surfaces such as outer cylindrical surfaces, arc surfaces, grooves, threads, chamfers, etc. B. Processing […]

Strategies to improve processing efficiency of flat bed CNC lathes Strategies to improve the processing efficiency of flat bed CNC lathes can be started from many aspects. The following are some specific strategies and suggestions: 1——Optimize processing technology and processing routes: Analyze the material, structural characteristics and geometric tolerance requirements of the parts to be […]