Power turret gear shaping is an important part of CNC lathe processing, which involves the combined application of power turret and gear shaping technology. The following is a detailed analysis of power turret gear shaping:

-

Power turret overview

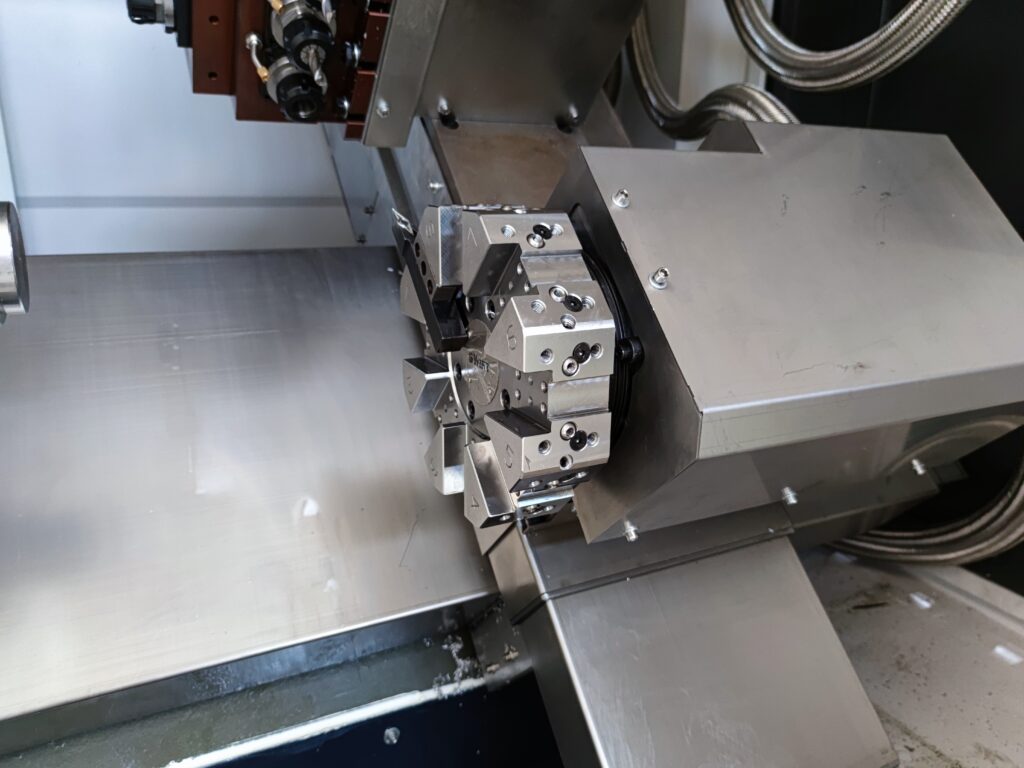

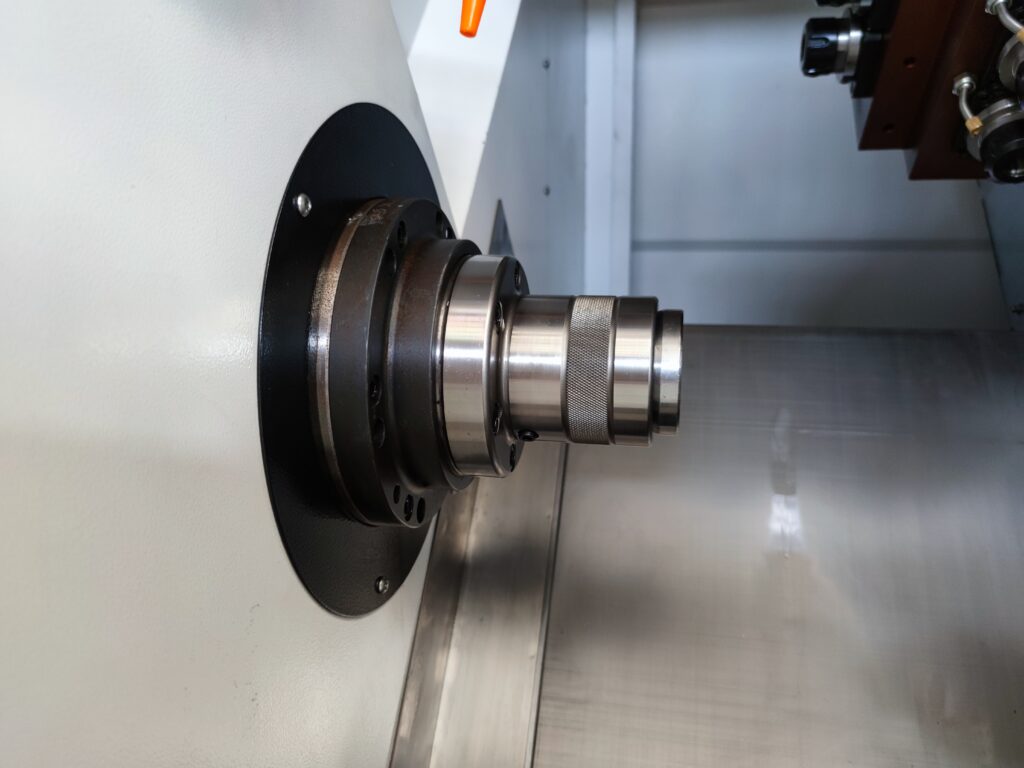

The power turret is an important component of CNC lathe, which is responsible for installing and driving various tools for cutting processing. The power turret usually has multiple stations and can automatically change tools to meet different processing requirements. During the processing, the power turret can accurately control the position and angle of the tool to ensure processing accuracy.

-

Introduction to gear shaping technology

Gear shaping is a process method that uses a gear shaping cutter to process the tooth surface of internal and external gears or racks by the development method or forming method. The gear shaping cutter is essentially a gear with front and rear angles and cutting edges. It is equivalent to a pair of gear pairs with no gap meshing with the workpiece. The gear shaping process includes cutting motion, tooth development motion, radial feed motion and tool letting motion.

-

Advantages of power turret gear shaping

High efficiency: The power turret can automatically change tools, reduce tool change time and manual intervention, and improve processing efficiency.

High precision: The power turret can accurately control the position and angle of the tool to ensure the accuracy of gear shaping.

Flexibility: The power turret can be installed with various types of gear shaping cutters to meet the processing needs of gears of different materials and shapes.

- Application of power turret gear shaping

Power turret gear shaping is widely used in the fields of automobile, aerospace, machinery manufacturing, etc., especially in the processing of high-precision gears and complex tooth shapes. Through the precise control of the power turret and the flexible application of gear shaping technology, efficient and high-precision gear processing can be achieved.

- Precautions for gear shaping in power turret

Tool selection: Select the appropriate gear shaping cutter according to the processing material and tooth shape requirements to ensure processing quality and efficiency.

Cutting parameter setting: Reasonably set parameters such as cutting speed, feed rate and cutting depth to avoid tool overload and excessive surface roughness of the workpiece.

Machine tool maintenance: Clean, lubricate and inspect the machine tool regularly to ensure the normal operation and accuracy of each component of the machine tool.

Operation specification: Operators should strictly follow the operating procedures to ensure the safety and stability of the processing process.

In summary, gear shaping with a power turret is an important technology in CNC lathe processing. It achieves efficient and high-precision gear processing through precise control of the power turret and flexible application of gear shaping technology. In practical applications, attention should be paid to issues such as tool selection, cutting parameter setting, machine tool maintenance and operating specifications to ensure processing quality and efficiency.