The operation of the live turret of a CNC lathe is a complex process involving multiple steps and precautions. The following are the basic steps and key points for the operation of the power turret of a CNC lathe, sorted out based on existing information:

I. Startup and preparation

1. Startup inspection:

o Turn on the main power supply to ensure that the CNC machine tool is ready for startup.

o Check the connection status of the hydraulic, pneumatic, feed axes and other auxiliary equipment of the machine tool to ensure that everything is normal.

o Start the CNC system and the machine tool, and check whether normal information is displayed on the CNC system.

2. Tool preparation:

o The tools used should be consistent with the specifications allowed by the machine tool, and severely damaged tools should be replaced in time.

o After the tool is installed, a test cut should be made to ensure the cutting effect and correct tool installation.

II. Workpiece program editing and input

• Before processing, the processing technology and processing program of the workpiece should be analyzed and compiled first.

• If the machining program of the workpiece is long or complex, it is recommended to use a programming machine or computer for programming, and then back it up to the CNC system of the CNC machine tool through a floppy disk, U disk or communication interface.

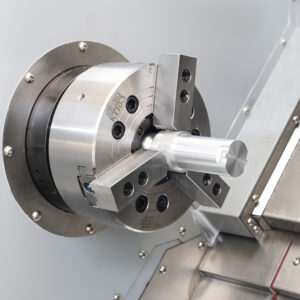

III. Power turret operation

1. Automatic tool change:

o The power turret of the CNC lathe usually has an automatic tool change function, which controls the turret to rotate to the specified position through the CNC system to realize automatic tool change.

o During the automatic tool change process, ensure that the CNC system program is correct and pay close attention to the movement of the turret and the tool.

2. Manual adjustment:

o In some cases, it may be necessary to manually adjust the position of the turret or the installation angle of the tool. At this time, ensure that the machine tool is in a stopped state and follow the instructions in the machine tool operation manual.

IV. Process monitoring

• During the machining process, the operator should pay close attention to the operating status of the machine tool, including tool wear, cutting fluid supply status, spindle speed and feed speed.

• It is forbidden to touch the tool tip and iron chips with your hands. Iron chips must be cleaned with an iron hook or brush.

• It is forbidden to touch the rotating spindle, workpiece or other moving parts with your hands or in any other way.

• It is forbidden to measure or change speed during processing, and it is forbidden to wipe the workpiece with cotton thread or clean the machine tool.

V. Shutdown and Cleaning

• After processing, the machine tool spindle should be stopped first, and then the power supply and main power supply on the machine tool operation panel should be turned off in turn.

• Remove chips, wipe the machine tool, and keep the machine tool and the environment clean.

• Check or replace the oil inspection plate on the worn machine tool guide rail, and check the status of lubricating oil and coolant, and add or replace them in time.

VI. Safety Precautions

• The operator should wear personal protective equipment such as work clothes, safety shoes, work hats and protective glasses.

• Be careful not to move or damage the warning signs installed on the machine tool.

• The working space should be large enough to avoid placing obstacles around the machine tool.

• The operator should be familiar with the location of the emergency stop button of the machine tool and press it quickly in an emergency.

The operation of the CNC lathe power turret requires the operator to have rich experience and professional knowledge, and strictly abide by the machine tool operating procedures and safety precautions. Through correct operation and maintenance, the stable operation of the machine tool and the efficient improvement of processing quality can be ensured.