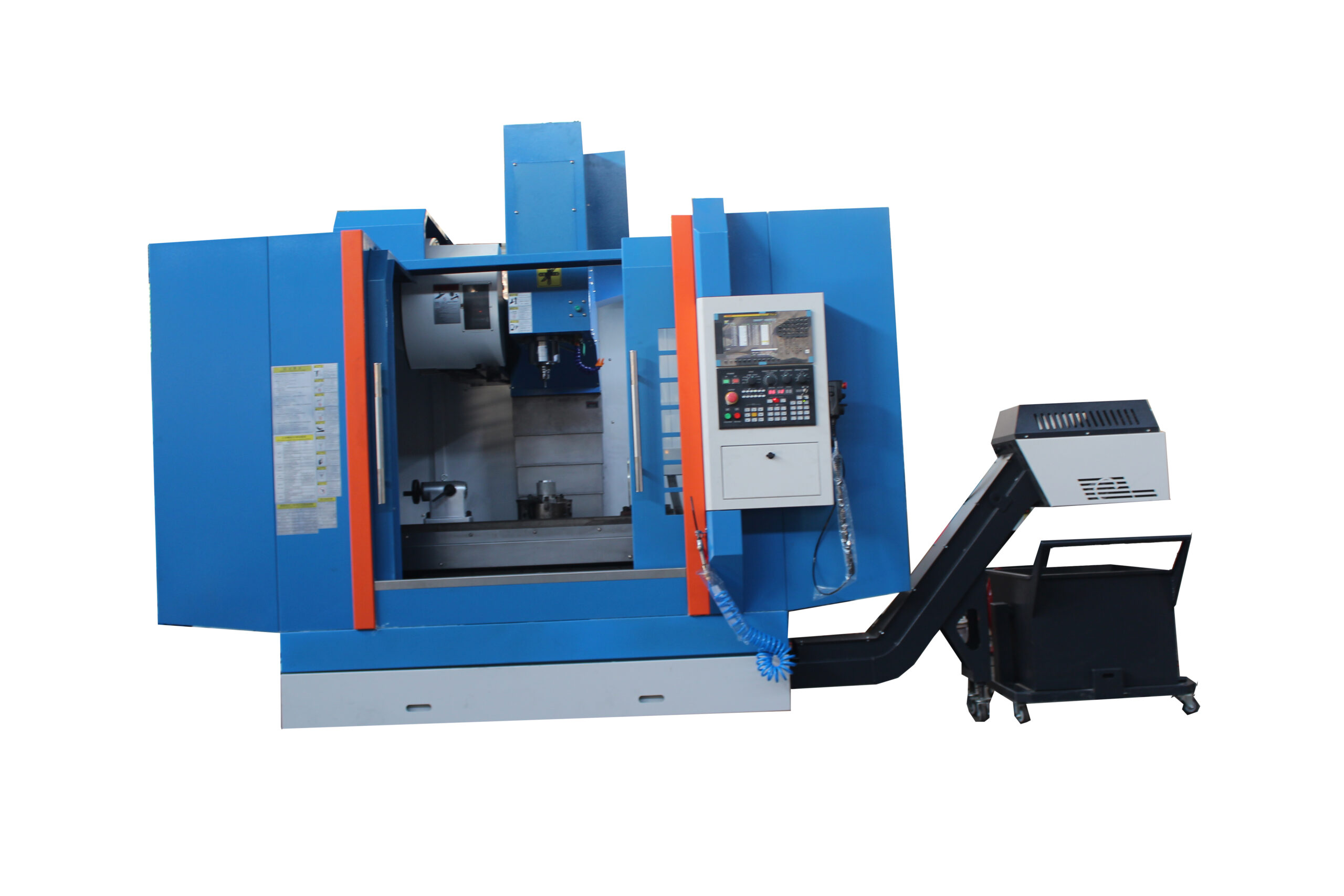

To master the operation of slant bed CNC lathe with Y-axis control, there are many key aspects involved, including machine preparation, programming, tool setting, machining process monitoring and troubleshooting. The following is a detailed tutorial outline:

I. Machine preparation

1. Environmental check:

o Ensure that the environment around the machine is clean, free of debris and obstacles to avoid affecting the operation of the machine.

o Check whether the power supply and air supply of the machine are normal to ensure that the machine can start normally.

2. System check:

o Check whether the parameters and programs of the CNC system are correct to ensure that the machine can operate normally according to the preset program.

o Check whether the transmission system, guide rails, lead screws and other components of the Y-axis (and other axes) are well lubricated and have no abnormal wear or looseness.

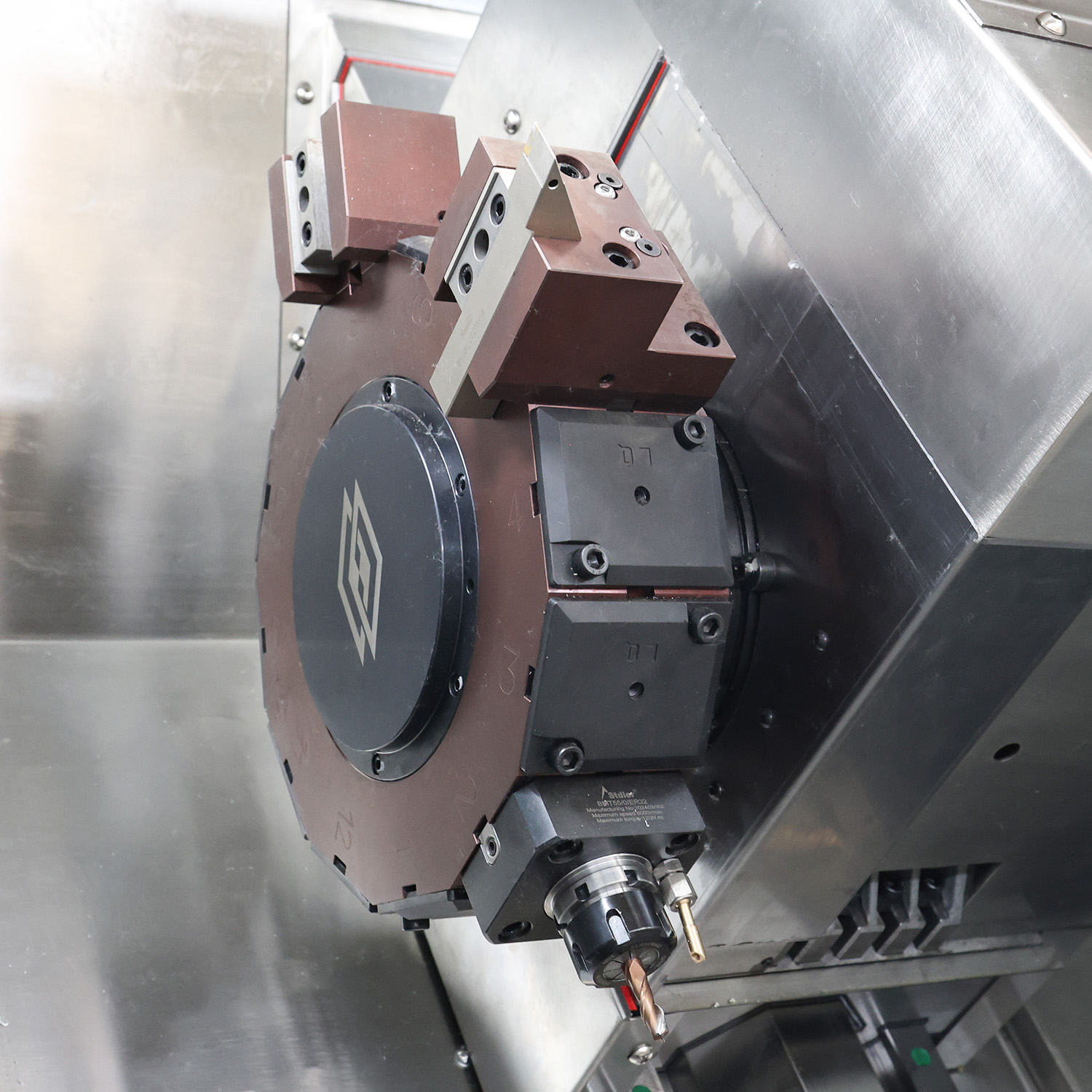

3. Tool and fixture preparation:

o Prepare the tools and materials required for processing to ensure that the tools are sharp and undamaged.

o Select appropriate fixtures to ensure that the workpiece can be clamped stably to avoid vibration or displacement during processing.

2. Programming

1. Workpiece analysis:

o Analyze the part drawings to understand the requirements of the workpiece’s shape, structure, dimensional accuracy and surface roughness.

o Determine the processing sequence and processing path, and reasonably plan the motion trajectory of the Y axis (and other axes).

2. Programming method:

o CNC programming methods include manual programming and automatic programming. For complex workpieces, it is recommended to use automatic programming software (such as UG, SolidCAM, etc.) for programming.

o During the programming process, pay attention to the setting of parameters such as the coordinate value, feed speed, and spindle speed of the Y axis (and other axes) to ensure the accuracy and stability of the processing process.

3. Tool radius compensation:

o Most CNC lathes have an automatic tool radius compensation function. When programming, this function should be fully utilized to improve the processing accuracy of the workpiece.

o For CNC lathes that do not have an automatic tool radius compensation function, the compensation amount must be calculated first when programming, and corresponding adjustments must be made in the program.

3. Tool setting

1. Tool setting method:

o Commonly used tool setting methods include trial cutting method, tool setting instrument method, etc. Select the appropriate tool setting method according to the specific situation of the machine tool and the requirements of the workpiece.

o During the tool setting process, pay attention to the changes in the coordinate values of the Y axis (and other axes) to ensure that the tool setting is accurate.

2. Tool setting steps:

o Move the tool to a safe position near the workpiece.

o Gradually adjust the tool position until the tool contacts the surface of the workpiece and produces slight cutting.

o Record the coordinate value at this time as the tool setting point coordinate and input it into the CNC system.

4. Processing process monitoring

1. Real-time monitoring:

o During the processing, observe the changes in parameters such as the movement state of the Y axis (and other axes), spindle speed, feed speed, etc. through the real-time monitoring function of the CNC system.

o Pay attention to the processing of the workpiece, and promptly discover and handle abnormal conditions.

2. Fault handling:

o If a machine tool fault or abnormal condition is found (such as tool damage, workpiece displacement, etc.), it should be stopped immediately and the cause should be checked.

o Take appropriate treatment measures according to the cause of the fault, such as replacing the tool, adjusting the fixture, modifying the program, etc.

5. Precautions

1. Safe operation:

o Strictly abide by the safety operating procedures during operation to ensure personal and equipment safety.

o It is prohibited to make unnecessary adjustments and operations during the operation of the machine tool.

2. Maintenance:

o Regularly maintain the machine tool to keep it clean and in good operating condition.

o Check and replace worn and damaged parts to ensure the accuracy and stability of the machine tool.

3. Skill improvement:

o Continuously learn and master new CNC technologies and operating methods to improve your skills and operating efficiency.

o Actively participate in training and exchange activities, share experiences and insights with peers, and jointly improve the level of CNC processing.

Through the mastery and practice of the above steps and precautions, you can gradually master the operation of the Y-axis controlled inclined bed CNC lathe and achieve efficient and accurate CNC processing.