As an important equipment in the field of modern mechanical processing, the slant bed CNC lathe has won wide recognition for its efficient and precise processing performance. Among them, the power turret and Y-axis, as key components of the slant bed CNC lathe, play a vital role. The following is a detailed introduction to these two components:

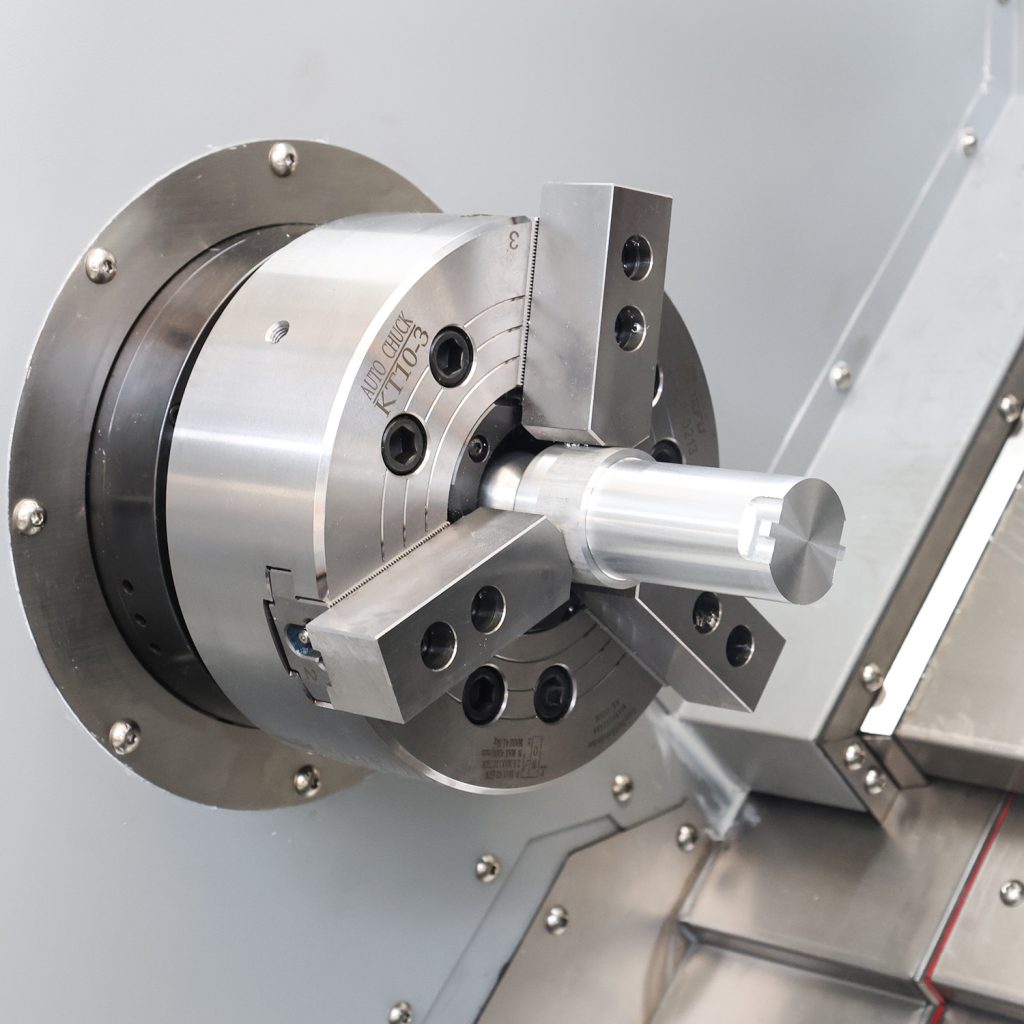

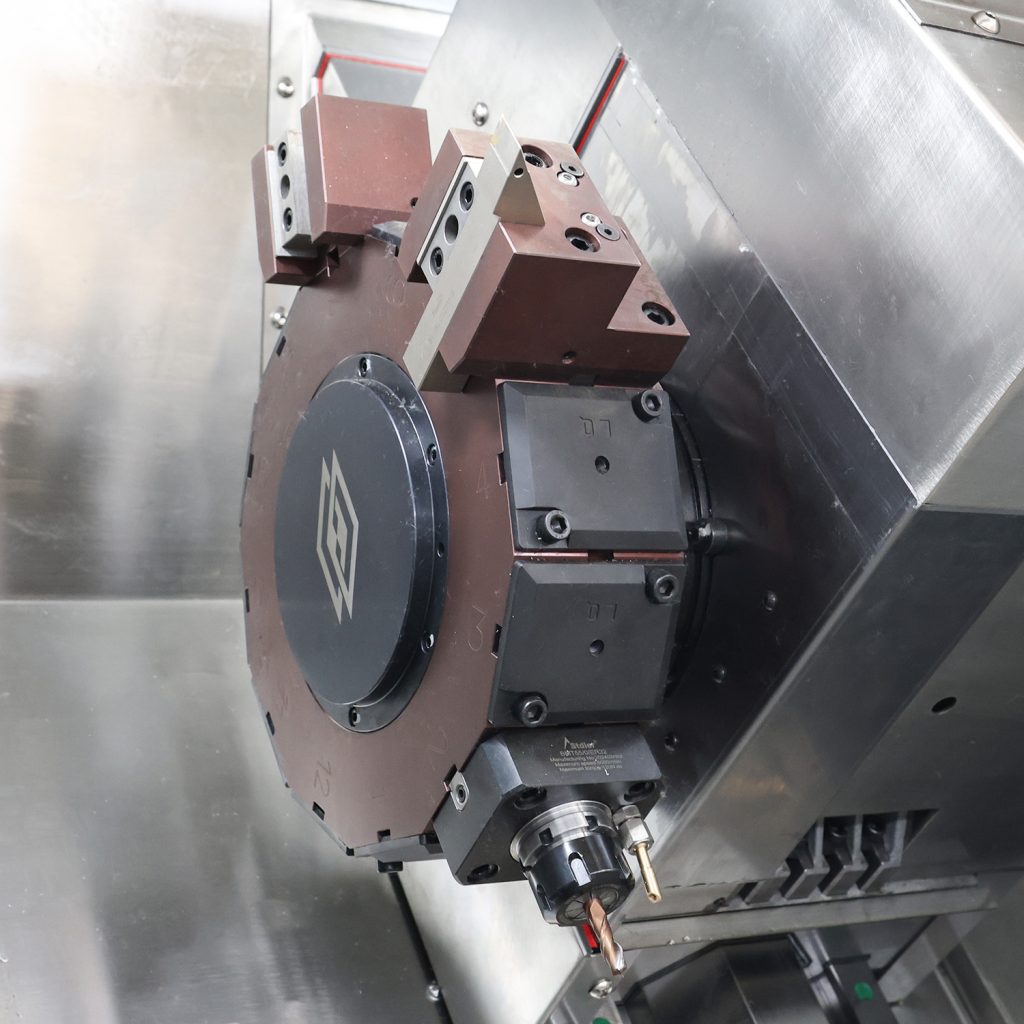

Power turret

The power turret is an important component of the slant bed CNC lathe. It is responsible for automatically changing tools and performing cutting tasks during the processing process. The design and functional features of the power turret are as follows:

1. Multi-station design:

o The power turret is usually equipped with multiple stations, each of which can be installed with different types of tools.

o This design enables the CNC lathe to automatically select and replace the appropriate tool as needed during the processing, greatly improving the processing efficiency and flexibility.

2. High-precision positioning:

o The power turret is equipped with a high-precision positioning device to ensure the positioning accuracy of the tool during the replacement process.

o This high-precision positioning ensures the processing accuracy, allowing the CNC lathe to process more complex and higher precision workpieces.

3. Fast tool change function:

o The power turret has a fast tool change function, which can complete the tool change in a short time.

o This reduces non-processing time and improves overall processing efficiency.

4. High rigidity design:

o The power turret usually adopts a high rigidity design to withstand the cutting force and vibration generated during the processing.

o This design ensures the stability and service life of the power turret.

Y-axis

The Y-axis is a key component for horizontal feeding of workpieces in slant bed CNC lathes. The design and functional characteristics of the Y-axis are as follows:

1. High-precision guide rails:

o The Y-axis usually adopts high-precision guide rails, such as linear guide rails or rolling guide rails.

o These guide rails have the advantages of low friction coefficient, smooth movement and high precision, which ensures the stability and precision of the Y-axis during the processing.

2. High-performance servo drive:

o The Y-axis is driven by a high-performance servo motor, which converts the motor’s rotational motion into linear motion through a transmission mechanism (such as a ball screw).

o The servo motor has the characteristics of precise control and rapid response, which can ensure the position accuracy and speed control of the Y-axis during the processing.

3. Closed-loop control system:

o The Y-axis adopts a closed-loop control system, and the position information is monitored in real time through detection devices such as grating scales and magnetic scales.

o These detection devices feed back the position information to the CNC system, and the CNC system adjusts according to the feedback information to ensure the high precision and stability of the Y-axis during the processing.

4. Wide range of application scenarios:

o The Y-axis has a wide range of application scenarios and is suitable for the processing of various complex-shaped workpieces.

o Especially in occasions where high-precision horizontal feeding is required, such as contour processing of automotive parts and aerospace devices, the Y-axis plays a vital role.

In summary, the power turret and the Y-axis, as key components of the inclined bed CNC lathe, play a vital role in the processing process. Their design and functional characteristics ensure the efficient and precise processing performance of the CNC lathe, enabling the CNC lathe to adapt to the processing needs of workpieces of different materials and shapes.