To judge whether the four-axis CNC machining center meets your processing needs, it is necessary to comprehensively evaluate the specific requirements of the processing task, the equipment performance parameters and the actual production scenario. The following are the detailed analysis steps:

1. Core elements with clear processing requirements

A. Part geometric complexity

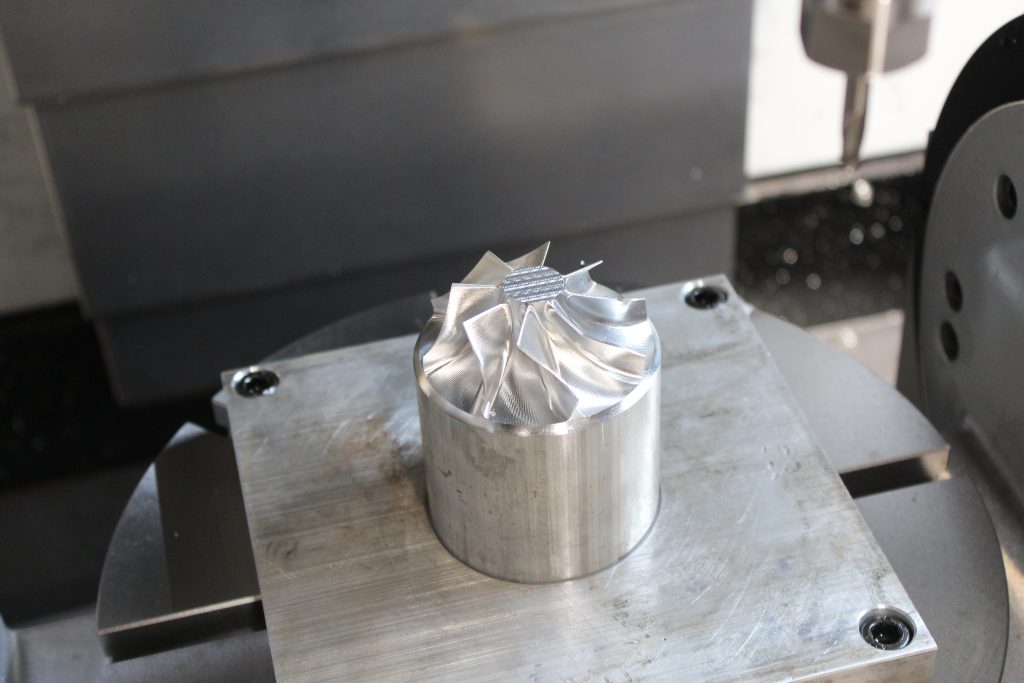

a) Four-axis capability: It can process parts with spiral surfaces, inclined surfaces, and rotations (requires rotation processing around the axis), or complete multi-faceted processing (such as box-type parts) through one clamping.

b) Determine whether it is sufficient: If the part requires five-axis linkage (such as complex surfaces, and the tool and part are seriously related), it needs to be upgraded to five axes; if the part is single-sided + rotary axis assisted (such as milling spiral grooves), four axes can meet it.

B. Accuracy and surface quality

a) Comparison parameters: Check the positioning accuracy of the equipment (within ±0.005mm), repeat positioning accuracy (within ±0.003mm) and spindle bearing runout (≤0.005mm).

b) Verification method: test processing standard parts (such as circular array holes, bevels), measure actual size and surface finish (Ra≤1.6μm).

C. Material and batch requirements

a) Material vehicle: The four-axis can process metals such as aluminum, steel, and titanium alloys, but high-rigidity materials (such as hardened steel) need to confirm the rotation power (≥15kW) and spindle spindle.

b) Batch efficiency: The four-axis improves efficiency by reducing the number of clamping times and is suitable for small and medium batches (such as 10-50 pieces in a single clamping).

2. Evaluate key performance of equipment

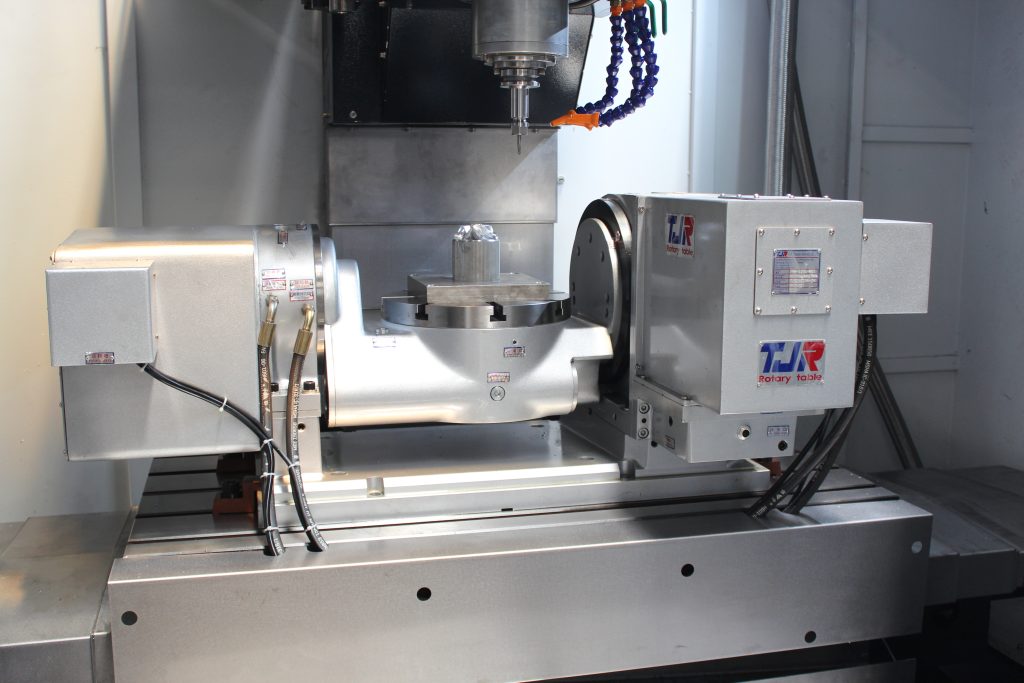

A. Rotary axis type and stroke

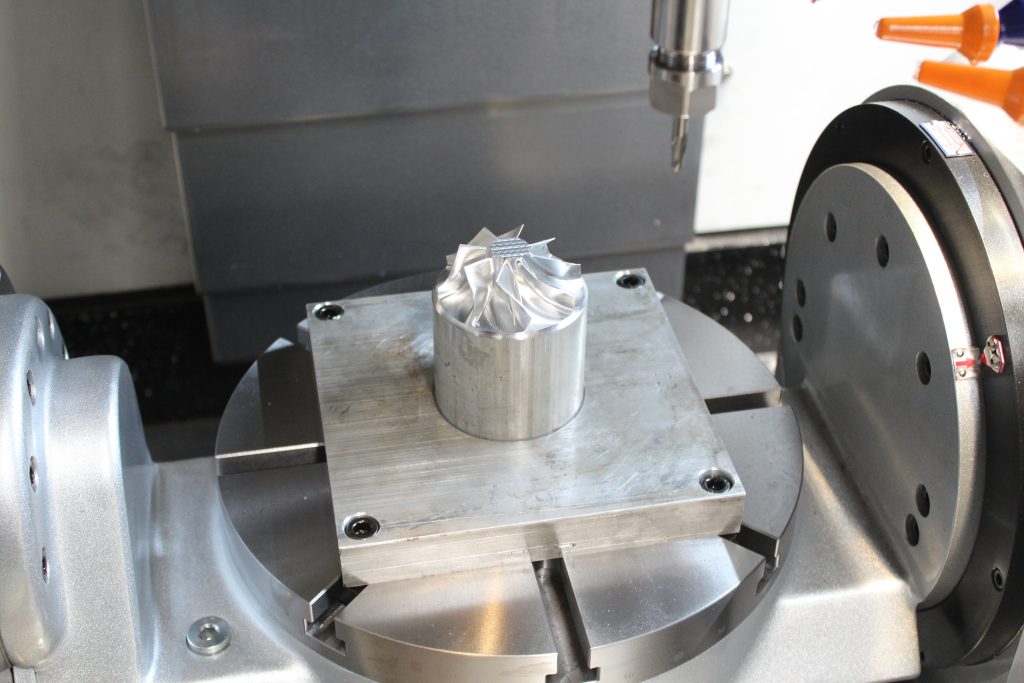

a) Rotary table type (fourth axis): suitable for small and medium-sized parts, with high rotation accuracy, but limited load-bearing capacity (≤500kg).

b) Swing head type (fourth axis): suitable for large parts, but the swing head structure may affect rigidity.

c) Stroke matching: The rotation axis stroke needs to cover part of the maximum processing angle (such as C-axis ±90° stroke is required to process a 90° bevel).

B. Rotation and feed system

a) Spindle: high-speed processing (such as aluminum) requires ≥12,000rpm, heavy load requires high aluminum alloy (≥200Nm).

b) Feed speed: fast moving speed ≥36m/min, cutting feed ≥10m/min, with the entire non-processing time.

C. Control system and software compatibility

a) Controller: FANUC, Siemens and other systems need to support four-axis linkage programmer.

b) CAM software: confirm whether Mastercam, UG, etc. support four-axis tool path generation (such as multi-axis coordinates, surface projection processing).

3. Actual scene production configuration

A. Shop layout and clamping method

a) Space limitation: Four-axis equipment occupies about 4-6㎡, and the storage channel needs to be constructed.

b) Required fixture design: The center of gravity balance is considered for the rotation axis clamping (such as using a three-jaw chuck or a special fixture).

B. Operation and maintenance costs

a) Staff skills: Four-axis programming requires familiarity with G code and post-processing, and staff need to receive multi-axis training.

b) Maintenance cycle: Rotary bearings and rotary axes need to be lubricated regularly (every 500 hours), and rotary axes need to be checked for gear wear.

C. Scalability and upgrade potential

a) Programming interface: Confirm whether the equipment supports subsequent upgrades to five axes (such as adding a B axis).

b) Additional functions: Whether tool change (ATC), automatic workpiece measurement, etc. meet automation requirements.

4. Verification and decision-making recommendations

A. Trial processing test

a) Provide typical part drawings and require suppliers to conduct trial processing to detect key dimensions, geometric tolerances and processing time.

B. Cost-effectiveness analysis

a) Compare the investment in three-axis, four-axis, and five-axis equipment (the price of a four-axis is about 60%-70% of that of a five-axis) and long-term capacity improvement.

C. Supplier technical support

a) Confirm whether the supplier provides process optimization, tool recommendation and after-sales training services.

Summary

If your processing needs focus on single-sided complex features, multi-sided clamping optimization or batch accuracy requirements, a four-axis machining center is the best choice for production. If it involves five-axis linkage surface processing, super coordinates (<0.005mm) or aviation-grade complex parts, you need to consider five-axis equipment. It is recommended to combine trial processing data with long-term capacity planning for comprehensive decision-making.