Choosing the right tool is essential to improving the processing effect of CNC milling machines. Here are some specific selection strategies to help optimize the processing process and improve the processing quality:

1. Characteristics and types of tools

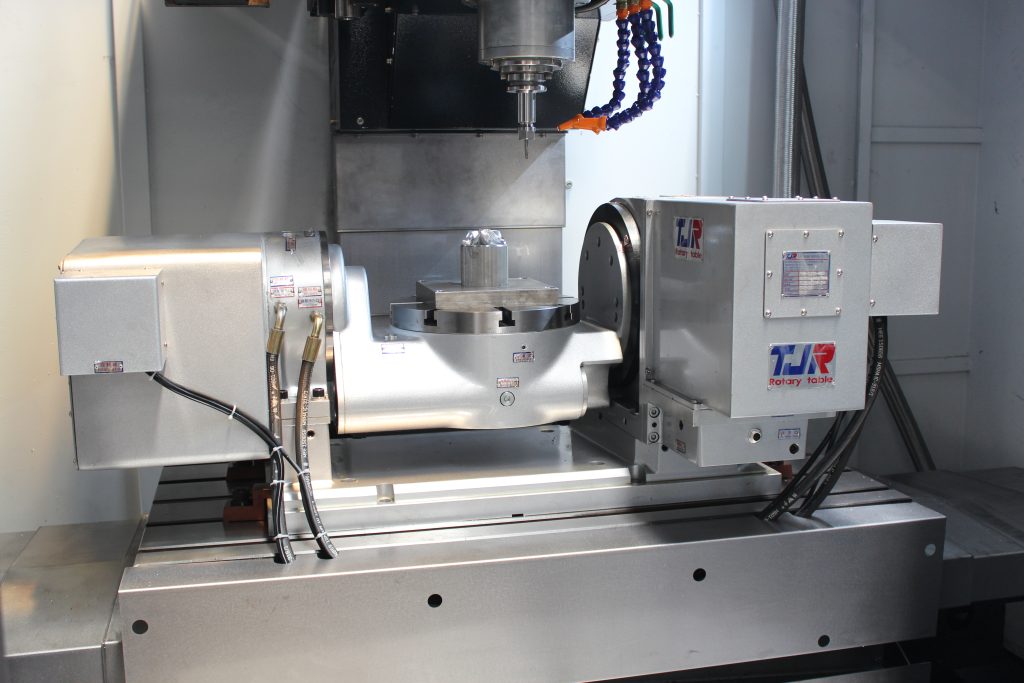

There are many types of CNC milling machine processing tools, which are mainly divided into two categories: milling tools and hole processing tools to adapt to the characteristics of high speed, high efficiency and high degree of automation of CNC machine tools. Tools are moving towards standardization, generalization and modularization, and there are also special tools for various special purposes.

2. General principles for tool selection

When selecting tools, the following general principles should be followed:

1) Convenient installation and adjustment: The tool should be easy to install and adjust to reduce the time for changing tools and setting processing parameters.

2) Good reliability: The tool should have good reliability to ensure that there will be no failure or damage during the processing.

3) Good rigidity: The tool should have sufficient rigidity to resist deformation and vibration during the processing.

4) High durability and precision: The tool should have high durability and precision to maintain the stability and accuracy of the processing.

3. Select tools according to processing requirements

1) Select tools according to the surface size of the workpiece:

a) When processing the contour around the plane parts, end mills are often used.

b) When milling planes, carbide blade milling cutters should be selected.

c) When processing bosses and grooves, high-speed steel end mills should be selected.

d) When processing the surface of the blank or rough processing of the hole, a corn milling cutter with carbide blades can be selected.

e) For the processing of some three-dimensional surfaces and variable bevel contours, disc milling cutters, round nose cutters, and flat cutters are selected for rough processing, and ball-end milling cutters, annular milling cutters, and conical milling cutters are selected for fine processing.

2) Select tools according to the surface shape of the workpiece:

a) When processing molds, since the cutting speed of the end of the ball-end tool is zero, the ball-end milling cutter is often used for fine processing of curved surfaces.

3) Select tools according to the processing material:

a) Carbide milling cutters have good hot hardness and wear resistance, but poor impact resistance, and are suitable for use in CNC machining centers.

b) High-speed steel milling cutters are cheap and tough, but they are not strong and have poor wear resistance, so they are suitable for ordinary milling machines.

4. Consider the order of tool arrangement and process parameters

1. Arrange the order of tool arrangement reasonably:

a) The principles of concentrated clamping of processes, separate use of rough and fine machining tools, first surface and then hole, first surface finishing and then two-dimensional contour finishing should be followed.

b) Reasonably use the automatic tool change function of CNC machine tools to improve production efficiency.

c) Minimize the number of tools to reduce processing costs.

2. Optimize process parameters:

a) Reasonably set the process parameters of CNC milling machines such as feed speed, spindle speed, and cutting depth to improve processing efficiency.

b) Through reasonable parameter selection, low processing efficiency caused by cutting too slowly or too deep can be avoided.

5. Regularly check and replace tools

The tools will gradually wear out during use, affecting the processing quality and efficiency. Therefore, tools with severe wear should be checked and replaced regularly to keep the tools in good condition.

In summary, choosing the right tool is crucial to improving the processing effect of CNC milling machines. When selecting tools, factors such as tool characteristics, types, processing requirements, and process parameters should be fully considered to ensure the stability and accuracy of the processing process.