In today’s manufacturing industry, four-axis CNC machining centers have become the preferred equipment for many companies with their efficient and precise processing capabilities. Whether it is a CNC milling machine, a metal processing center or other types of CNC equipment, it is crucial to choose a four-axis CNC machining center that suits your needs. This article will provide you with a detailed purchasing guide to help you choose the most suitable equipment for you among the CNC machining centers made in China.

1. Understand the basic characteristics of the four-axis CNC machining center

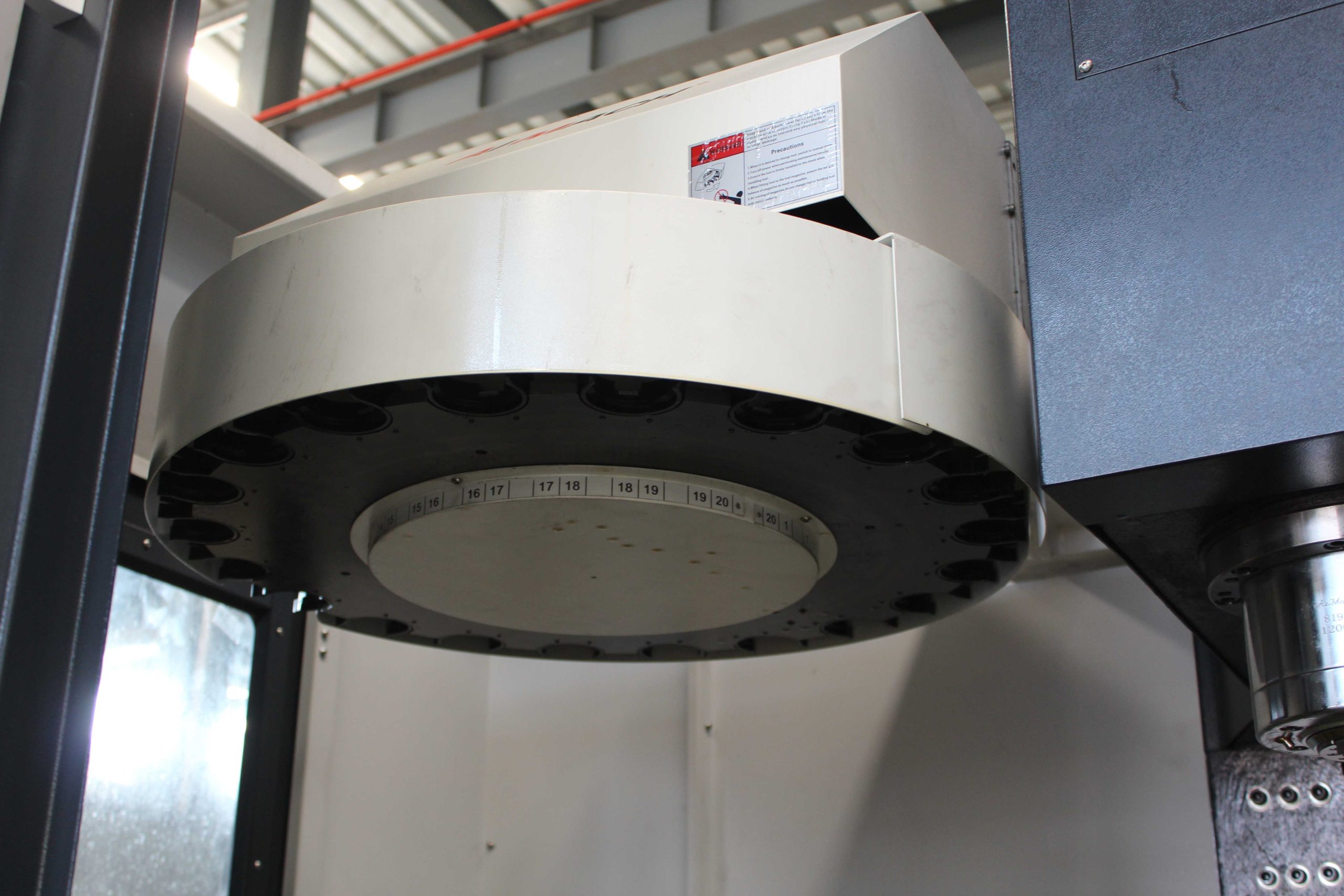

The four-axis CNC machining center is based on the traditional three-axis CNC machining center, adding a rotating axis (the fourth axis), thereby realizing the processing of complex curved surfaces and three-dimensional parts. This equipment has the characteristics of high precision, high efficiency and high flexibility, and is widely used in aerospace, automobile manufacturing, mold manufacturing and other fields.

2. Clarify purchasing needs

Before choosing a four-axis CNC machining center, you need to clarify your processing needs. This includes the type of processing material (such as metal, non-metal, etc.), the size and shape of the workpiece, the processing accuracy and surface quality requirements. At the same time, you also need to consider factors such as the production efficiency, degree of automation and convenience of maintenance of the equipment.

3. Evaluate equipment performance and accuracy

Positioning accuracy and repeatability: These are important indicators for measuring the performance of CNC machining centers. High positioning accuracy and repeatability can ensure the accuracy and consistency of the processed parts.

Processing range: According to your processing needs, choose equipment with an appropriate processing range. Make sure that the equipment can handle the size of the workpiece to be processed.

Spindle performance: The speed, power and rigidity of the spindle directly affect the processing efficiency and processing quality. Choosing a spindle with high speed, sufficient power and good rigidity can improve processing efficiency.

4. Consider equipment stability and reliability

The stability and reliability of the equipment are crucial to ensuring production efficiency and processing quality. When choosing, you can pay attention to information such as the average trouble-free working time of the equipment, maintenance cycle, and the supplier’s after-sales service policy.

5. Pay attention to CNC machining centers made in China

In recent years, China’s CNC machining center manufacturing industry has made great progress, and a number of excellent companies with independent intellectual property rights and core competitiveness have emerged. The CNC machining centers produced by these companies not only have stable performance and reliable quality, but also have relatively reasonable prices and high cost performance.

6. Choose a suitable fourth-axis configuration

The configuration of the fourth axis has an important impact on the performance of the four-axis CNC machining center. When choosing, you need to pay attention to factors such as the processing range of the fourth axis, the tailstock form, the braking method, and the compatibility with the control system. At the same time, you also need to consider the installation and maintenance costs of the fourth axis.

7. Understand after-sales service and technical support

High-quality after-sales service and technical support are important guarantees to ensure the stable operation of the equipment and extend its service life. When choosing, you can understand the supplier’s after-sales service policy and technical support capabilities to ensure that you can get timely and professional help during use.

8. Comprehensive comparison and selection

After clarifying the procurement needs and evaluating the performance of the equipment, you can comprehensively compare CNC machining centers of different brands and models and choose the most cost-effective equipment. At the same time, you can also consider negotiating with suppliers for more favorable prices and more complete after-sales service.

In short, choosing a suitable four-axis CNC machining center requires comprehensive consideration of multiple factors. By clarifying your purchasing needs, evaluating equipment performance and accuracy, considering equipment stability and reliability, paying attention to CNC machining centers made in China, and choosing the appropriate fourth-axis configuration, you can select the equipment that best suits you and provide strong support for your company’s production and development.