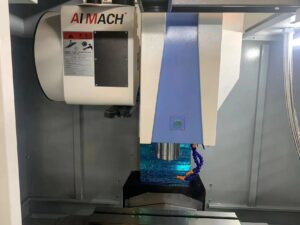

More and more customers will choose the fourth axis when purchasing CNC machining machines.

In CNC machining centers, the application of the 4th axis can greatly improve processing efficiency.

1——Achieve high-precision processing of spatially complex curved surfaces

A:The four-axis CNC machining center makes the processing of space curved surfaces possible by introducing a rotation axis, thereby greatly improving the processing accuracy, quality and efficiency of free space curved surfaces.

. The core of this technology lies in the high degree of integration and optimization of machine tool control systems, servo drive systems and mechanical structures. Through precise programming and control systems, machine tools can achieve micron-level processing accuracy to meet the processing needs of various high-precision parts. It is suitable for polyhedral parts, spirals with rotation angles (such as cylindrical oil grooves), spiral grooves, Processing of complex parts such as cylindrical cams and cycloids.

B:It can process different workpieces, including those that cannot be processed by three-axis machining machines or that require too long clamping. For example, long-axis surface machining can be completed with a four-axis rotary table, thus expanding the machining possibilities.

C:At the same time, the four-axis CNC machining center has flexible and diverse processing methods, including positioning processing and linked processing modes. Positioning processing means that before the actual cutting of the workpiece, the rotation axis of the machine tool is rotated to a fixed orientation, and then the actual cutting begins. Simultaneous machining means that during the actual cutting process of the machine tool, a rotating axis simultaneously participates in the movement of the X, Y and Z axes of the machine tool. The choice of these processing methods depends on the specific processing needs and workpiece characteristics.

-

Application fields of high-precision processing technology

A: Aerospace field: Aerospace components have extremely high requirements for precision and reliability. Four-axis CNC machining centers can accurately process complex aerospace parts, such as engine blades, turbine disks, etc., providing strong support for the development of the aerospace industry.

B: Automobile manufacturing field: With the continuous development of the automobile industry, the shape and structure of automobile parts are becoming more and more complex. The four-axis CNC machining center can process high-precision automotive parts, such as engine blocks, crankshafts, etc., improving the performance and reliability of the vehicle.

C: Mold manufacturing field: Mold manufacturing has very high requirements for precision and surface quality. The four-axis CNC machining center can accurately process various complex molds, improve the accuracy and life of the molds, and reduce production costs.

-

Advantages of four-axis CNC machining center

A:Efficiency: Through automation and intelligent technology, the four-axis CNC machining center realizes a fast and efficient processing process and improves production efficiency.

B: Flexibility: The four-axis CNC machining center has a high degree of flexibility and can process parts of different shapes and sizes to meet diverse production needs.

C: High precision: The four-axis CNC machining center has high processing precision, which can meet the processing needs of high-precision parts and improve product quality.

-

How to improve the machining accuracy of four-axis CNC machining center

A: Optimize the machine tool structure: By improving the rigidity and stability of the machine tool, reduce vibration and deformation during the processing process, and improve processing accuracy.

B:Use high-precision cutting tools and fixtures: Choosing high-quality cutting tools and fixtures can reduce errors and wear during processing and improve processing accuracy.

C: Fine programming and debugging: Through fine programming and debugging, the processing paths and parameters are optimized to achieve high-precision processing effects.

In order to achieve high-precision machining, the operation and maintenance of four-axis CNC machining centers are also crucial. It is necessary to ensure the clamping accuracy and stability of the workpiece, reasonably select cutting parameters and tools, pay attention to cooling and lubrication during processing, and strengthen equipment maintenance. These measures can effectively improve processing quality and efficiency, extend tool life, and reduce production costs.