The fault diagnosis and troubleshooting methods of flat bed CNC lathes involve many aspects, including the use of the machine tool’s self-diagnosis function, functional program testing, isolation method, local heating method, knocking method, comparison method and other technical means, as well as specific troubleshooting methods for specific fault types. The following is a detailed explanation of these methods:

1. Fault diagnosis method

Self-diagnosis function method

Description: Modern CNC systems have powerful self-diagnosis functions that can monitor the hardware and software working status of the system at any time. Once an abnormality is found, the alarm information will be displayed on the CRT or the general cause of the fault will be indicated by the LED.

Application: The self-diagnosis function can display the interface signal status between the system and the host, so as to determine whether the fault is in the mechanical part or in the CNC system part.

Functional program test method

Description: Write functional test programs such as linear positioning, circular interpolation, spiral cutting, etc., input them into the CNC system and run them to check the accuracy of the machine tool functions, so as to determine the possible causes of the fault.

Application: Suitable for detecting whether the general and special functions of the CNC system are normal.

Isolation method

Description: Narrow the scope of the fault by disconnecting some control circuits, so as to locate the fault point more accurately.

Application: In complex circuits, the isolation method can effectively reduce the scope of investigation.

Tapping method

Description: Detect the fault location by tapping the suspicious point. Since the CNC system is composed of multiple printed circuit boards, incorrect welding or poor contact may cause faults. Tapping the suspicious point may cause the fault to reappear.

Application: Suitable for detecting poor contact or welding problems.

Comparison method

Description: Use the detection terminal to compare the difference between the normal printed circuit board and the faulty printed circuit board, and analyze the cause and location of the fault by detecting the voltage and waveform.

Application: Suitable for situations where precise measurement and comparison are required.

2. Specific troubleshooting methods

Emergency stop alarm after the machine tool is started

Inspection: Check the input and output status of the machine tool in the PLC state of the CNC system, and check whether the emergency stop switch is damaged.

Processing: Repair or replace the damaged parts according to the inspection results.

The tool position does not change in manual mode

Inspection: First check the input and output signal status, and then check the relay indicator light and contactor in the relevant signal circuit and electrical cabinet.

Processing: Repair or replace damaged signal circuits and electrical components.

The cooler does not work in manual mode

Inspection: Check the input and output signal status of the cooler, and check the circuit according to the circuit diagram.

Handling: Repair the circuit short circuit and open circuit problems to ensure that the cooler is powered on normally.

The circuit breaker trips after power-on

Inspection: Check the circuit and find the reason for the circuit breaker tripping. It may be that the rated current is less than the current required by the machine tool or the three-phase power is short-circuited.

Handling: Adjust the circuit or replace the circuit breaker according to the inspection results.

Fault alarm occurs in the position loop of the CNC system

Inspection: Detect the position measurement circuit, measuring elements and position loop control interface, etc.

Handling: Repair open circuit, damaged elements and interface signal problems.

Feed system failure

Inspection: Check the servo motor and driver, the guide rail and screw of the feed axis, the oil pressure value and the oil circuit, etc.

Handling: Repair or replace damaged parts and adjust the feed parameters.

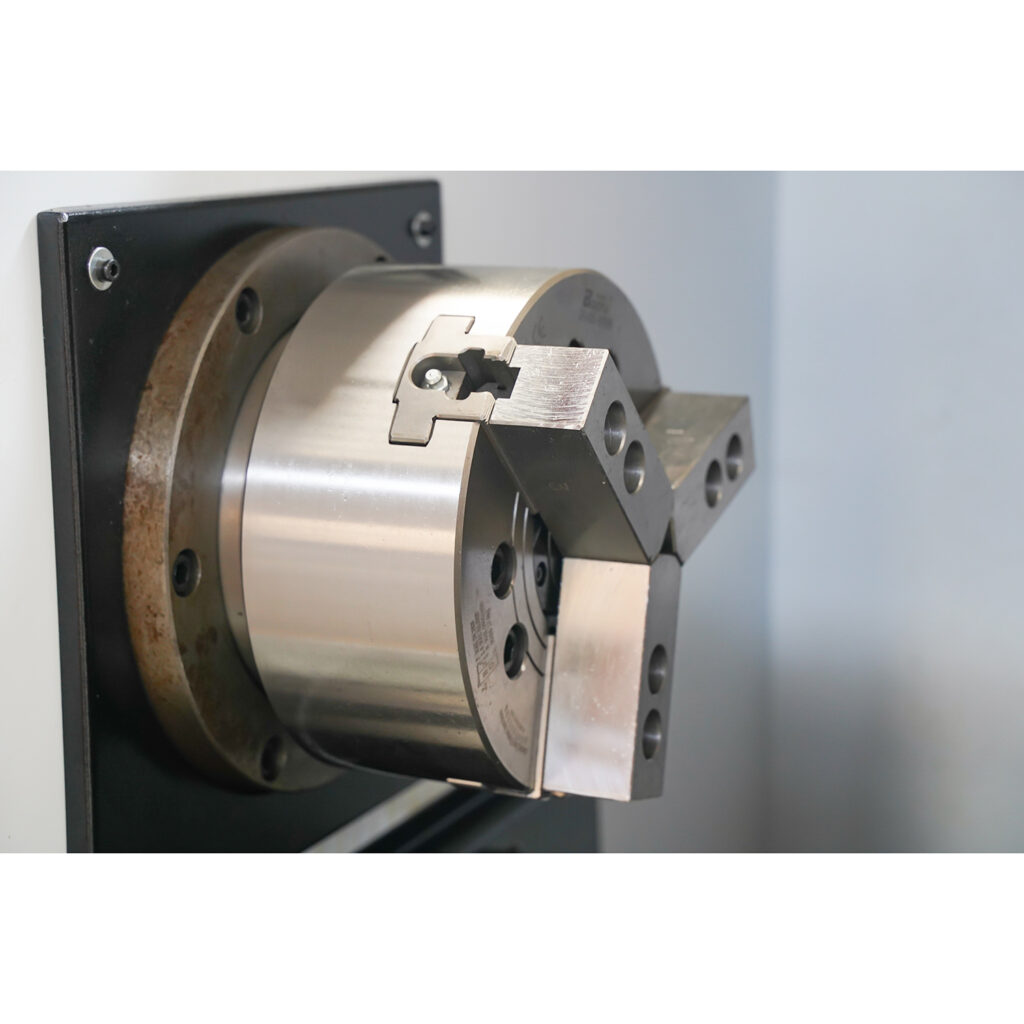

Spindle system failure

Inspection: Check the spindle motor and bearings, the taper and circumference of the spindle, etc.

Handling: Clean and add lubricating oil, adjust or replace parts, and check the spindle feed parameter settings.

3. Summary

Fault diagnosis and troubleshooting of flat bed CNC lathes require the comprehensive use of multiple methods and technical means. In actual operation, appropriate methods should be selected according to specific circumstances, and troubleshooting and processing should be carried out strictly in accordance with operating specifications. At the same time, strengthening the daily maintenance and care of machine tools is also an important measure to prevent faults.