The efficient use of powered turrets on inclined bed CNC lathes requires mastering a series of operating skills and maintenance knowledge. The following is an operating guide to help you make better use of the power turret to improve the processing efficiency and accuracy of your slant bed CNC lathe.

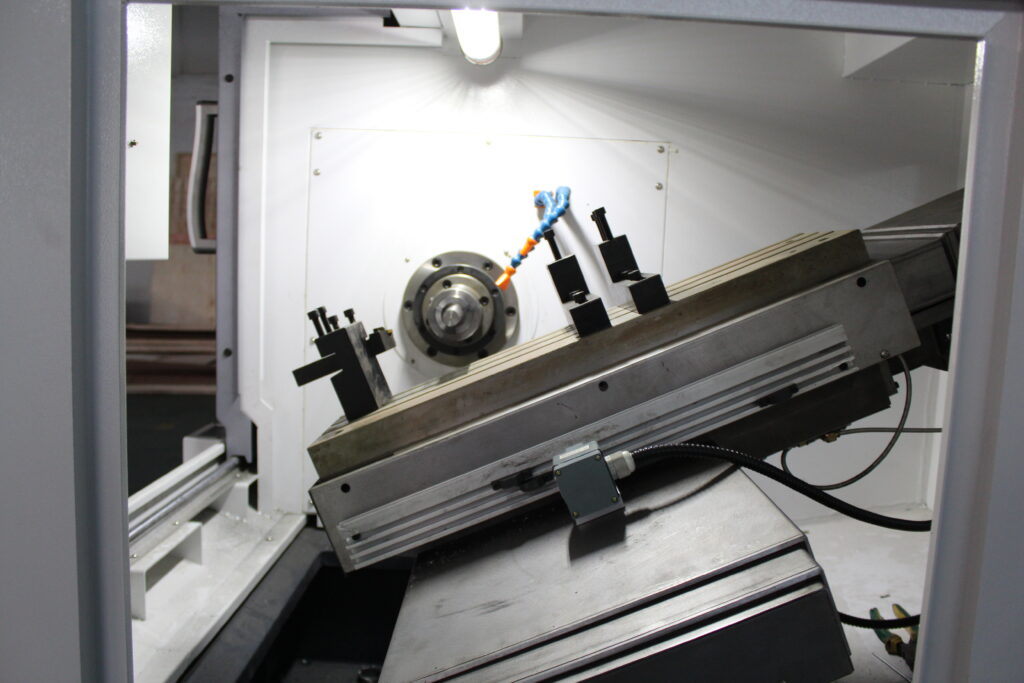

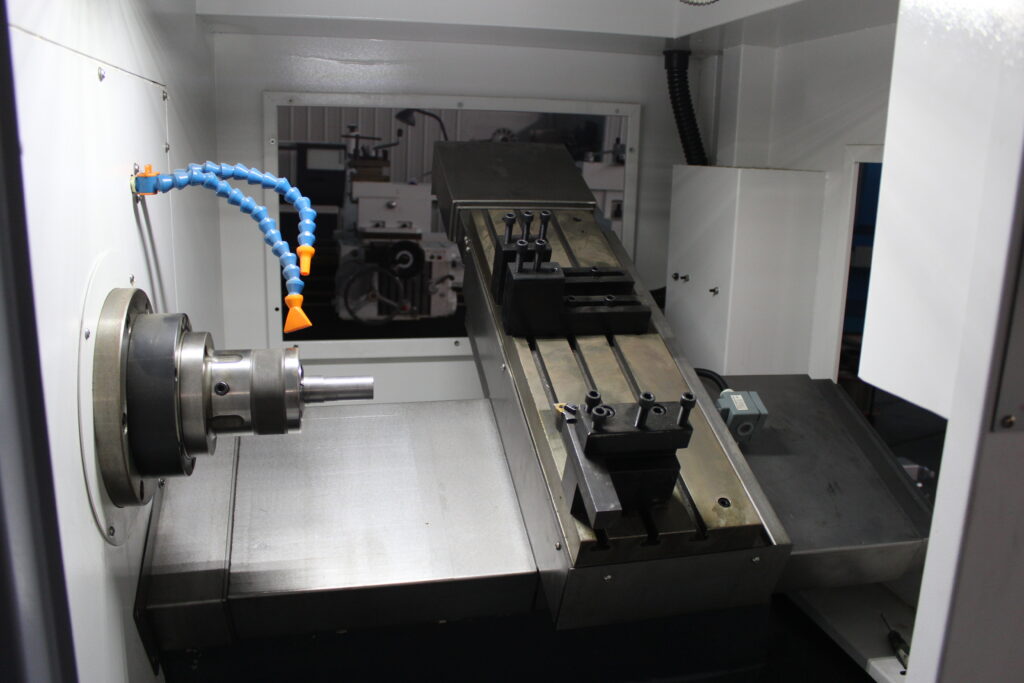

slant bed cnc lathe machine for metal workpiece,screw

-

Preparation before operation

Machine tool selection: Choose a suitable inclined bed CNC lathe based on factors such as processing needs, budget, and occasion. Ensure that the power turret of the machine tool has stable performance and can meet the processing requirements.

System proficiency: Proficient in the CNC system of CNC lathes, including basic operations and programming methods. You can refer to the operation manual or training materials provided by the manufacturer to learn.

Tool and Gauge Preparation: Prepare the required tools and gauges and ensure their accuracy and completeness. Understand the use and maintenance of cutting tools and measuring tools to ensure the smooth progress of the processing process.

-

Power tool turret operation skills

Tool changing operation: Be familiar with the tool changing process of the power turret to ensure that the tool changing process is fast and accurate. By quickly changing tools, tool changing time can be shortened and overall processing efficiency improved.

Tool adjustment: Set the tool appropriately according to the material, shape and size of the workpiece. Adjust the height and position of the tool holder to ensure that the distance between the tool and the workpiece is appropriate to avoid damage to the workpiece surface and the tool.

Processing parameter setting: Use the machine tool operation panel to set relevant parameters for processing the workpiece, including processing axial and axial feed speed, rotational speed, processing depth, etc. Ensure that the processing parameters are reasonable to improve processing accuracy and efficiency.

-

Safety precautions

Safe Operation: When operating a slant bed CNC lathe, make sure to follow safe operating procedures. Avoid using tools that are too long or too short and make sure the tool size meets requirements.

Troubleshooting: Monitor the operating status of the machine tool during processing and pay attention to the machine tool’s fault diagnosis system. When encountering a program error or abnormal situation, you should stop processing immediately and adjust the cutting parameters to avoid similar problems from happening again.

-

Machine tool care and maintenance

Regular cleaning: Clean cutting chips regularly to keep the machine tool clean and tidy.

Lubrication system maintenance: Maintain the normal operation of the lubrication system, check and replace lubricating oil regularly to ensure the normal operation of each component of the machine tool.

Tool maintenance: Regularly check the sharpness of the tools and replace severely worn tools in a timely manner to ensure processing quality and efficiency.

Through the above steps and precautions, you can make better use of the power turret to improve the processing efficiency and accuracy of the inclined bed CNC lathe. At the same time, continuous accumulation of practical experience and optimization of operating procedures will help you further improve production efficiency and product quality.