Flat-bed CNC lathe and vertical CNC lathe have significant differences in structure, function, application scenarios, etc. The following is a detailed comparison and selection suggestions between the two:

Difference

1. Structural characteristics

A. Flat-bed CNC lathe: Its bed design is relatively flat, which helps to provide stable support and ensure accuracy and stability during processing. At the same time, the flat bed design makes the overall structure of the machine tool compact and occupies a relatively small area.

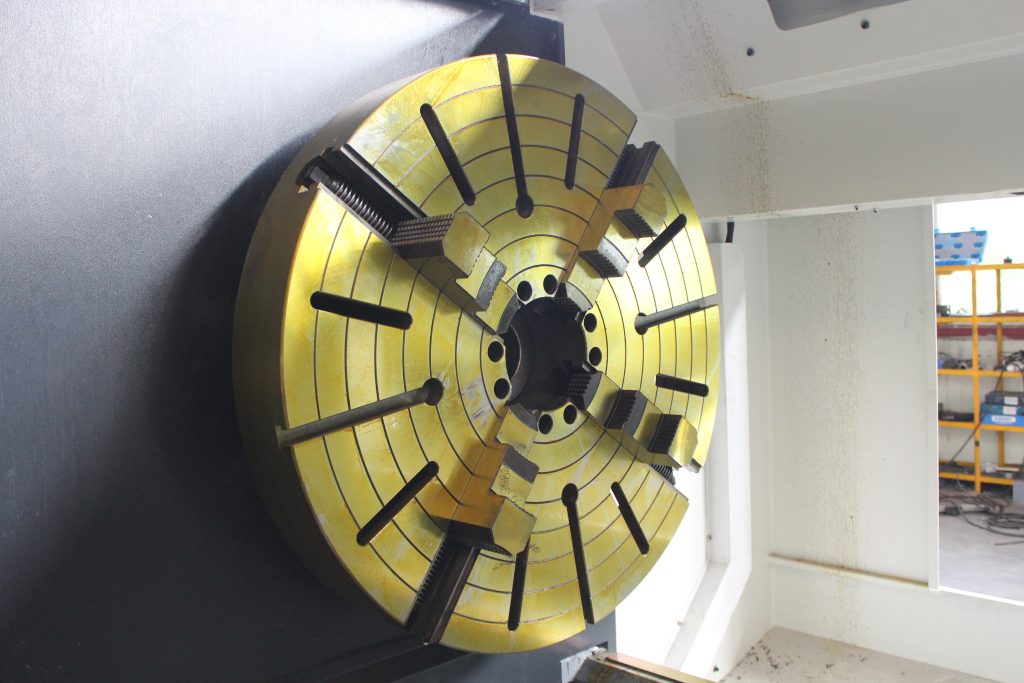

B. Vertical CNC lathe: Its spindle is perpendicular to the horizontal plane and is usually equipped with a circular worktable for clamping workpieces. The structure of the vertical lathe makes it more suitable for processing large and complex parts with large radial dimensions and relatively small axial dimensions.

2. Functions and applications

A. Flat-bed CNC lathe: It is suitable for batch processing and single-piece processing of various precision parts, such as processing instruments, meters, electronic connectors, optical devices, automobile and motorcycle parts, etc. It is usually equipped with an automatic feeder to realize automated production and improve production efficiency.

B. Vertical CNC lathe: Mainly used for turning of disc parts with large rotary diameter. Since the spindle is in the vertical direction, the operation is relatively simple and does not affect the accuracy of the mechanical object. Vertical lathes are also suitable for complex processing such as turning and drilling of medium-sized and small discs, shafts, and slender shaft parts.

3. Processing accuracy and efficiency

A. Flat bed CNC lathe: Known for its high precision, high rigidity, and high efficiency. The rigidity and processing accuracy of the machine tool are improved through the center installation and pre-stretched screw installation methods. At the same time, the tool holder structure saves tool change time and improves positioning accuracy and production efficiency.

B. Vertical CNC lathe: Although the processing accuracy and efficiency are also high, they may be limited by the size and shape of the workpiece. However, through advanced CNC technology and servo motor drive, vertical lathes can still achieve high-precision processing.

Selection suggestions

1. Choose according to processing needs: First, clarify the type, size, and accuracy requirements of the parts to be processed. If you mainly process small precision parts and need automated production, then a flat bed CNC lathe may be more suitable. If you process large disc parts or need complex processing, then a vertical CNC lathe may be more suitable.

2. Consider machine tool performance and stability: When choosing, pay attention to the machine tool’s rigidity, precision stability, cutting ability and other performance indicators. These performances will directly affect the processing quality and production efficiency.

3. Consider cost and maintenance: Different models of CNC lathes differ in price, maintenance cost and other aspects. When choosing, you should make a comprehensive consideration based on the budget and long-term operating costs. At the same time, you should also pay attention to the after-sales service and maintenance convenience of the machine tool.

In summary, flat bed CNC lathes and vertical CNC lathes have their own advantages and disadvantages. When choosing, you need to make a comprehensive consideration based on specific processing requirements, machine tool performance and stability, and cost and maintenance factors.