Five-axis CNC machining centers play an important role in modern manufacturing, especially in the high-precision machining of complex curved surface parts. The complex surface processing technology and practice of the five-axis CNC machining center will be discussed in detail below.

1—- multi-axis linkage

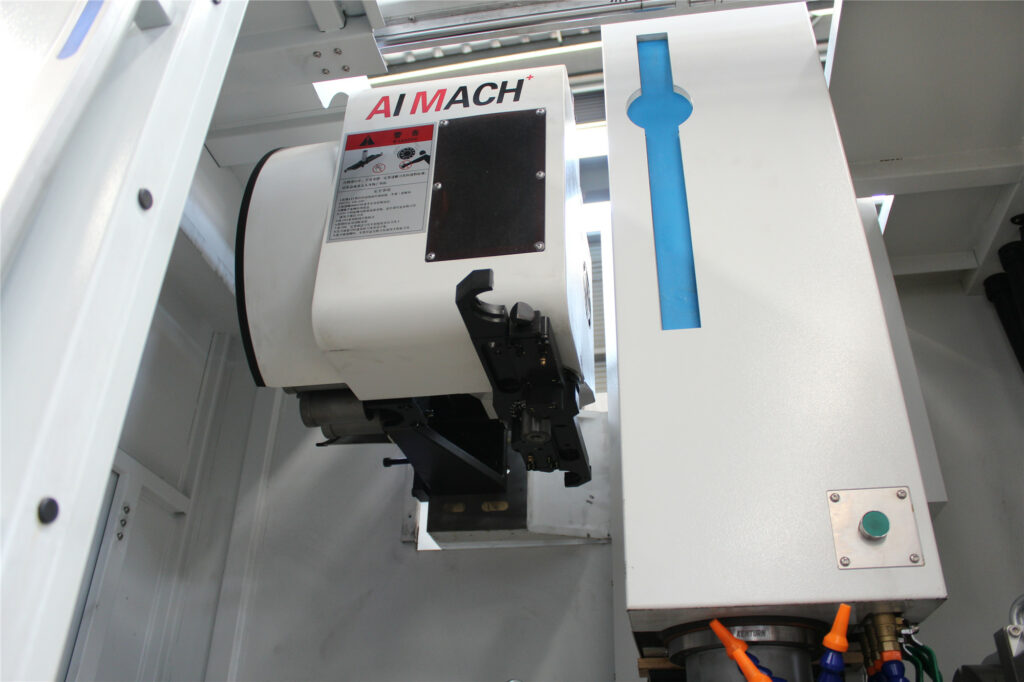

The five-axis CNC machining center realizes multi-axis linkage and completes the processing of multiple surfaces in one clamping, thereby reducing the number of tooling fixtures and improving processing accuracy and efficiency. This arrangement makes spindle processing very flexible, and the workbench can also be designed to be very large, suitable for processing large parts, such as aircraft fuselages or car casings. At the same time, five-axis linkage machining technology ensures that when processing complex-shaped surfaces, CNC interpolation motion is performed together through five independent axes to obtain smooth and smooth surfaces.

2—programming and tools

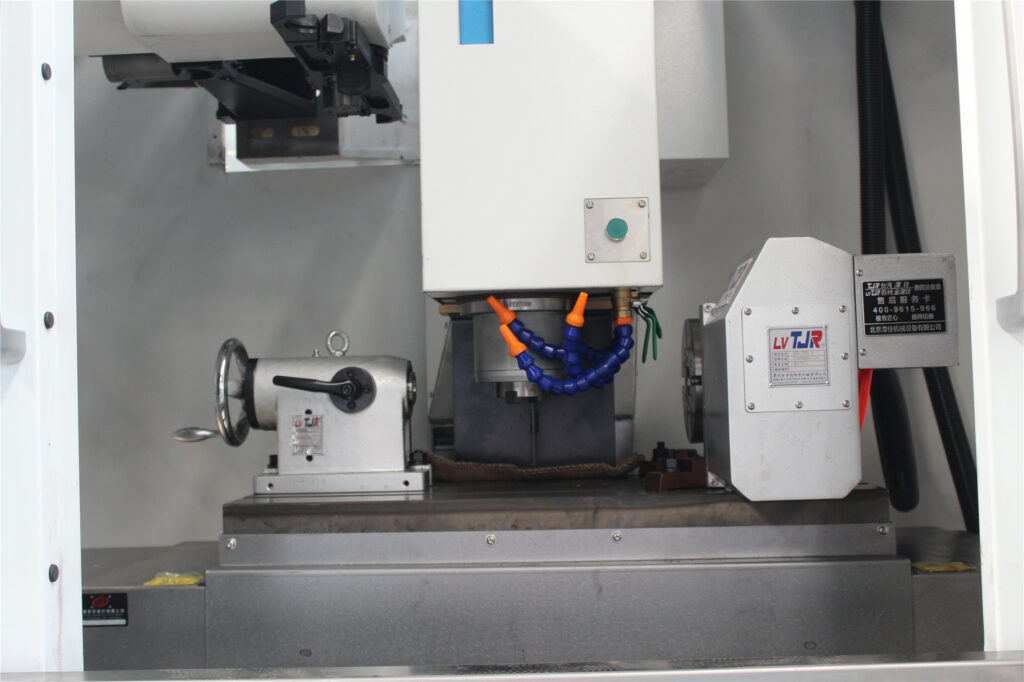

The complex surface processing of the five-axis CNC machining center involves many key links. Programming skills are crucial because the programming of five-axis CNC machine tools is more complex than traditional three-axis machine tools, and specific programming skills are required to achieve high-precision machining. Machine tool adjustment is also a key step. Professional technicians are required to adjust the machine tool to ensure the accuracy and stability of the machine tool. In addition, tool selection is equally important to achieve high-precision machining, and appropriate tools need to be selected to cope with the processing requirements of complex curved surfaces.

3—-CAD and CAM software

In order to optimize the machining process, modern five-axis CNC machining technology also combines advanced control methods and software tools. For example, machine learning-based methods are used to optimize processing parameters, significantly improving processing efficiency and accuracy. At the same time, CAD/CAM software plays an important role in complex surface processing and can achieve precise planning and simulation of the processing process. These software tools not only improve the convenience of programming, but also further improve processing quality and production efficiency by providing efficient processing strategies such as “surface projection finishing”.

4—- work is performed through simulated processing

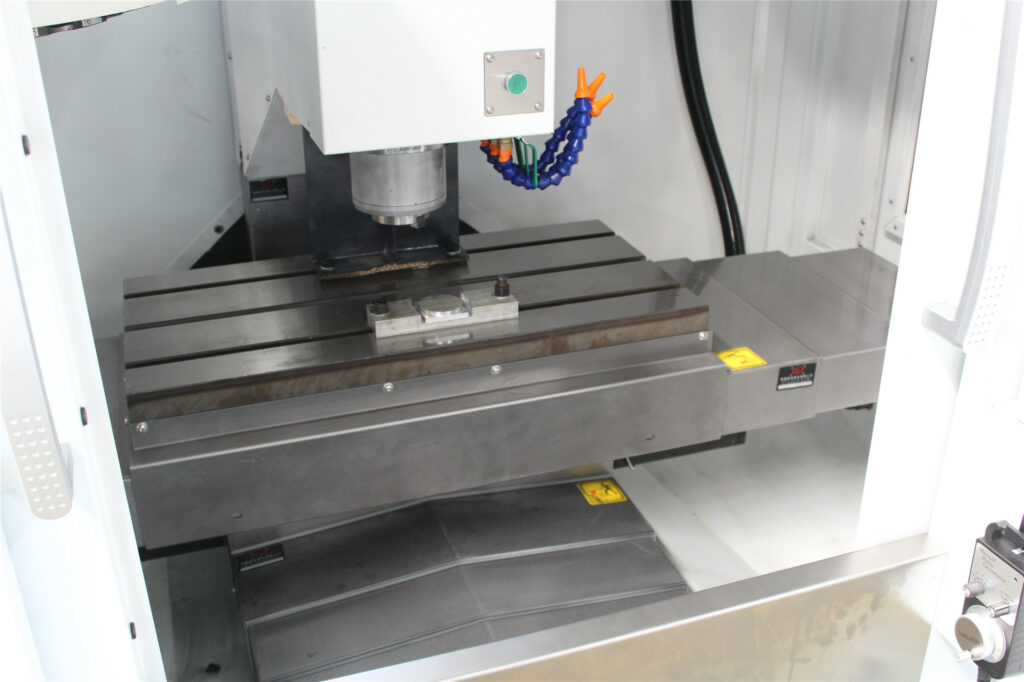

Considering the high cost of five-axis CNC machining equipment and the complexity of processing procedures, simulation verification technology has become an indispensable part. Before actual processing, experimental work is performed through simulated processing, which can predict and solve possible problems such as tool collision and interference, thereby ensuring the smooth progress of the processing process.

Five-axis CNC machining centers are also widely used in manufacturing fields such as mobile phone metal cases, back covers, handicrafts, metal molds, plexiglass processing, solid wood models, and mechanical accessories. Its powerful processing capabilities make the processing of complex-shaped workpieces more efficient and precise. The complex surface processing technology and practice of the five-axis CNC machining center involves optimization and innovation in many aspects. By combining high-precision processing, automated processing and strong adaptability, five-axis CNC machining centers play an increasingly important role in modern manufacturing, providing efficient and accurate solutions for the processing of various complex curved surface parts.