Using CNC milling machine processing center to accurately process complex parts requires comprehensive consideration of process planning, programming technology, equipment performance and quality control. The following are key steps and technical points:

1. Part analysis and process planning

A. Drawing integrity check: confirm whether the views, dimensions, tolerances and technical requirements (such as surface roughness, heat treatment) are complete.

B. Material property analysis: select tools, cutting parameters and cooling methods according to materials (such as aluminum alloy, titanium alloy, stainless steel).

C. Prediction of processing difficulties: identify complex curved surfaces, thin-walled structures, deep grooves and other areas that are easy to deform or difficult to process, and formulate targeted strategies.

D. Datum selection: follow the principles of “datum coincidence” and “datum unification”, give priority to the use of precision datum (machined surface) to reduce clamping errors.

2. Tool and fixture optimization

A.

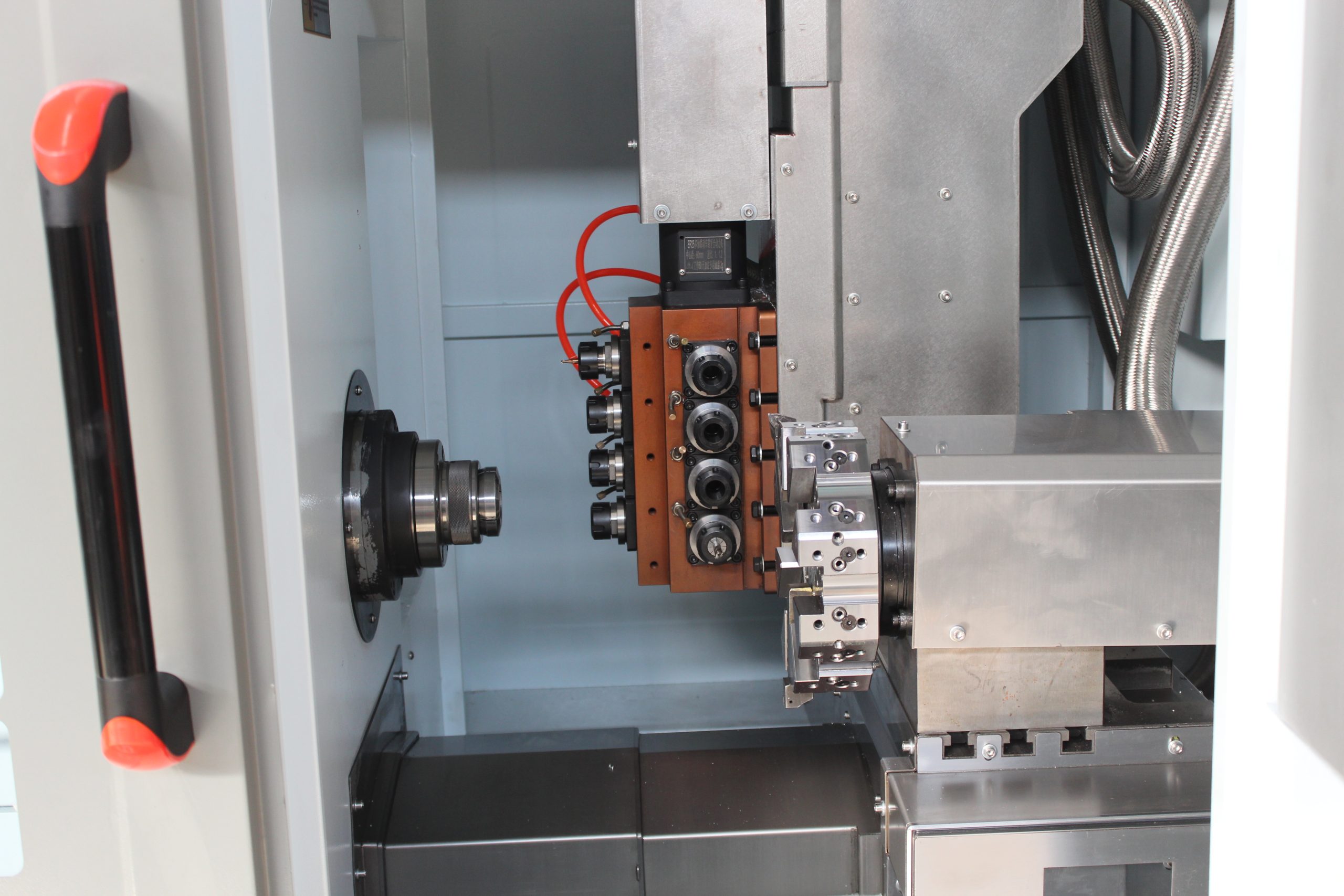

B. Tool selection:

a) Roughing: Use large-diameter tools (such as corn milling cutters) to quickly remove excess.

b) Finishing: Use ball-end cutters or tools with wiper blades to optimize surface quality.

c) Special tools: such as coated tools (to improve wear resistance) and solid carbide tools (suitable for high-speed cutting).

C. Fixture design:

a) Use high-precision fixtures (such as hydraulic fixtures and vacuum suction cups) to ensure the stability of the workpiece.

b) Complex parts can be clamped in multiple stations to reduce secondary positioning errors.

3. CNC programming technology

A. Programming method:

a) Automatic programming (CAM software): Generate tool paths using UG, Mastercam, etc. to support complex surface processing.

b) Manual programming: For simple features (such as hole processing), combine G codes (such as G54 coordinate system offset, G41/G42 tool compensation).

B. Tool path optimization:

a) Layered cutting: Avoid excessive cutting depth at one time, which may cause tool wear or deformation.

b) Contour processing: Suitable for curved surfaces to keep the cutting load uniform.

c) Down milling strategy: reduce flank wear and improve surface quality (especially for high alloy steel).

4. Cutting parameter setting

A. Rough machining:

a) Cutting depth (ap): as large as possible (e.g. 1-3mm), but the rigidity of the machine tool needs to be considered.

b) Feed rate (F): higher value (e.g. 1000-2000mm/min) to improve efficiency.

c) Spindle speed (S): calculated according to tool material and diameter (e.g. 8000-12000rpm for carbide tools).

B. Finishing:

a) Cutting depth (ap): 0.1-0.3mm to ensure surface finish.

b) Feed rate (F): lower value (e.g. 200-500mm/min) to reduce vibration.

c) Spindle speed (S): appropriately increased to optimize surface quality.

5. Processing strategy and precision control

A. Staged processing:

a) Roughing → semi-finishing → finishing, gradually approaching the final size.

b) Reserve 0.1-0.3mm margin for finishing to reduce the impact of thermal deformation.

B. Compensation technology:

a) Tool radius compensation (G41/G42): avoid contour errors.

b) Length compensation (G43): ensure Z-axis consistency of multiple tools.

C. Five-axis linkage processing:

a) Complex surfaces (such as impellers and molds) require five-axis equipment, and the number of clamping times is reduced by rotating the axis to avoid interference.

6. Quality inspection and optimization

A. Online inspection: Use machine tool probes to measure key dimensions in real time and correct processing parameters.

B. First article inspection: Use a three-coordinate measuring machine (CMM) to verify size and geometric tolerances.

C. Vibration monitoring: Monitor cutting forces through sensors and adjust parameters to prevent tool vibration.

D. Case reference

E.

F. Automobile engine parts: Using CNC double-sided milling machine, two surfaces can be processed in one clamping, reducing positioning errors and improving efficiency by 50%.

G. Aviation thin-walled parts: Using high-speed milling (HSM) combined with special aluminum alloy tools to control cutting thermal deformation and achieve ±0.02mm tolerance.

Summary

Precise processing of complex parts requires full control of the entire process from process design, programming optimization to equipment operation, focusing on benchmark unification, tool path optimization and parameter matching. Combining five-axis technology and real-time detection can significantly improve processing accuracy and efficiency.