When choosing a CNC lathe for metal processing according to processing needs, you need to consider several key factors to ensure that the selected equipment can meet specific production requirements. Here are some detailed steps and suggestions:

1. Clarify the characteristics of the processing material

• Hardness: For metal materials with higher hardness, you need to choose a CNC lathe with strong cutting force.

• Plasticity: Materials with better plasticity are not easy to break during processing, but they require higher precision and stability of the lathe.

• Toughness: Materials with strong toughness may generate greater cutting forces during cutting, so you need to choose a CNC lathe with a strong structure and good rigidity.

2. Determine the shape and size of the workpiece

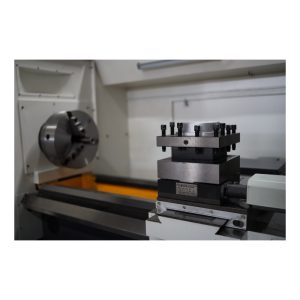

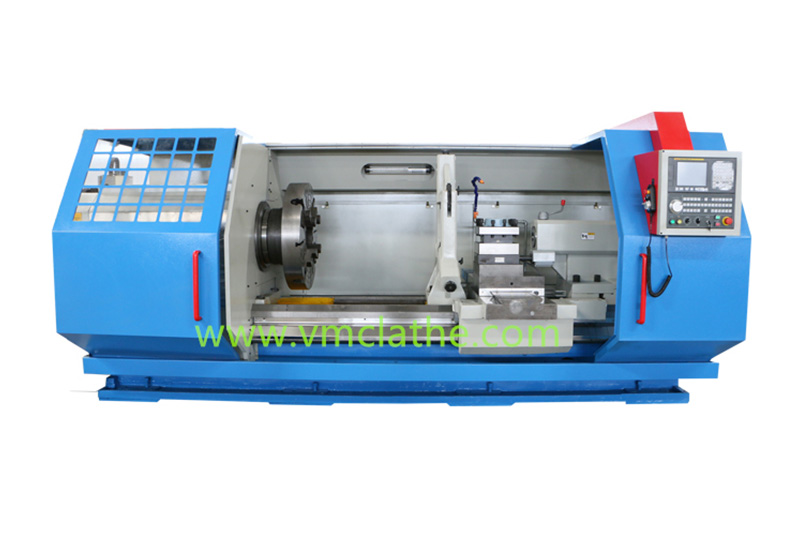

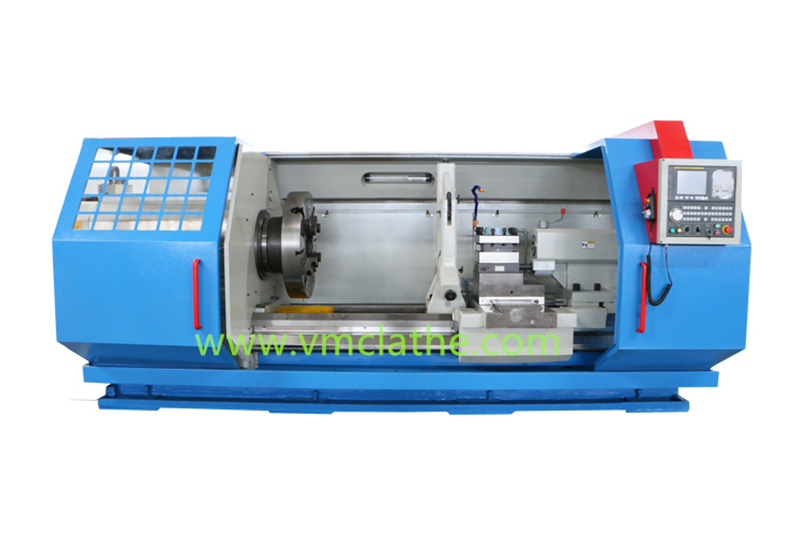

• Shape: CNC lathes are suitable for processing complex-shaped parts such as rotating bodies, threads, cams, etc. According to the specific shape of the part, choose the appropriate CNC lathe type and configuration.

• Size: Large-sized CNC lathes are required for processing large parts, while smaller equipment can be selected for processing small parts.

3. Consider processing accuracy requirements

• High-precision requirements: For parts that require high-precision processing, be sure to choose a CNC lathe with high precision. Pay attention to the equipment’s repeatability, positioning accuracy, and processing accuracy.

• General accuracy requirements: For parts with low accuracy requirements, you can choose a CNC lathe model with a higher cost-effectiveness.

4. Set the budget range

• Clear budget: Set a reasonable CNC lathe purchase budget based on the company’s financial situation and production needs.

• Comprehensive comparative analysis: Within the budget range, conduct a comprehensive comparative analysis of prices, functions, quality, etc. of CNC lathes of different brands and models to ensure that the best cost-effectiveness is selected.

5. Evaluate the manufacturer’s qualifications and services

• Qualification certification: Choose a CNC lathe manufacturer with complete qualifications and good reputation to ensure that the quality and performance of the equipment meet the standards.

• After-sales service: Understand the manufacturer’s after-sales service details, including support for equipment installation, commissioning, maintenance, etc., to ensure the stable operation of the equipment during the production process.

6. Consider other factors

• Automation level: According to production needs, choose a CNC lathe with a moderate degree of automation to improve production efficiency.

• Scalability: Consider the scalability of the equipment, such as whether it supports the replacement of multiple tools and fixtures to meet the changes in different processing needs in the future.

• Environmental protection and energy saving: Choose CNC lathes that meet environmental protection and energy saving standards to reduce production costs and reduce the impact on the environment.

In summary, choosing a CNC lathe for metal processing according to processing needs requires comprehensive consideration of multiple factors. By clarifying the characteristics of the processing material, determining the shape and size of the workpiece, considering the processing accuracy requirements, setting the budget range, evaluating the manufacturer’s qualifications and services, and considering other factors, you can ensure that the selected equipment can meet specific production requirements and improve production efficiency.