The Y-axis precise positioning technology of the slant bed CNC lathe is one of the key factors to improve processing quality. This technology achieves precise control of the Y-axis (usually corresponding to the lateral or feed direction of the machine tool) through a high-precision CNC system and advanced mechanical structure design, thereby ensuring the stability and accuracy of the processing process. The following is a detailed analysis of the Y-axis precise positioning technology of the slant bed CNC lathe and how it improves processing quality:

1. Overview of Y-axis precise positioning technology

The Y-axis precise positioning technology of the slant bed CNC lathe mainly relies on the following aspects:

1. High-precision CNC system: Modern CNC systems use advanced algorithms and high-speed processors to receive and process processing instructions in real time and accurately control the moving speed and position of the Y-axis. This high-precision control is the basis for achieving precise positioning.

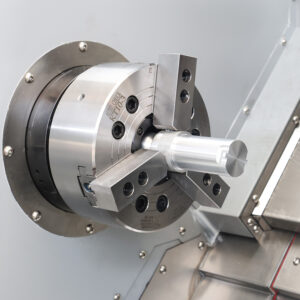

2. High-precision transmission device: Slant bed CNC lathes are usually equipped with high-precision ball screws, linear guides and other transmission devices, which have the characteristics of low friction, high rigidity and high precision, and can ensure the stability and accuracy of the Y-axis during movement.

2. Specific manifestations of improving processing quality

1. Reduce positioning error: Y-axis precise positioning technology can significantly reduce positioning error and ensure the dimensional accuracy of the workpiece in the Y-axis direction. This is especially important for parts that require high-precision processing, such as precision parts in aerospace, automobile manufacturing and other fields.

2. Improve surface quality: Due to the improved stability and accuracy of Y-axis movement, vibration and fluctuation during processing are reduced, which helps to improve the surface quality of the workpiece. This is especially important for parts that require high surface finish, such as molds, optical components, etc.

3. Shorten the processing cycle: High-precision positioning reduces the adjustment time and waiting time during processing, which helps to shorten the entire processing cycle. This is of great significance to improving production efficiency and reducing costs.

4. Enhance the adaptability of machine tools: Y-axis precise positioning technology enables the slant bed CNC lathe to more flexibly respond to various processing needs, including parts of different sizes, shapes and materials. This enhances the adaptability and flexibility of the machine tool and improves the overall efficiency of the production line.

III. Key technologies for achieving Y-axis precise positioning

1. High-precision servo control technology: Servo control technology is the core of achieving Y-axis precise positioning. By accurately controlling the speed and torque of the servo motor, the Y-axis can be accurately moved and positioned.

2. Precision mechanical structure design: The mechanical structure design of the slant bed CNC lathe fully considers the rigidity and precision requirements. By optimizing the bed structure, transmission device and support method, the stability and accuracy of the Y-axis during movement can be ensured.

In summary, the Y-axis precise positioning technology of the slant bed CNC lathe realizes the precise control and positioning of the Y-axis through the synergy of high-precision CNC system, high-precision transmission device and precision measurement and feedback system. This technology not only improves the dimensional accuracy and surface quality of the workpiece, but also shortens the processing cycle and enhances the adaptability and flexibility of the machine tool. In the future development, with the continuous upgrading of CNC technology and the continuous expansion of application fields, the Y-axis precise positioning technology of inclined bed CNC lathes will play a more important role.