CNC lathe selection guide: How to choose a suitable flat bed CNC lathe

Choosing a suitable flat bed CNC lathe is a key step to ensure processing quality and efficiency. The following is a CNC lathe selection guide to help you choose a suitable flat bed CNC lathe:

1.

Clarify needs and goals

A. Type of workpiece to be processed: Understand the type of workpiece to be processed, such as plates, bars, pipes, etc., as well as the size and shape of the workpiece.

B. Machining accuracy and surface quality: Clarify the required machining accuracy and surface quality requirements to select a suitable CNC lathe.

C. Processing efficiency: According to production needs, determine the required processing efficiency to select a CNC lathe with sufficient processing capabilities.

2.

Examine the performance parameters of CNC lathes

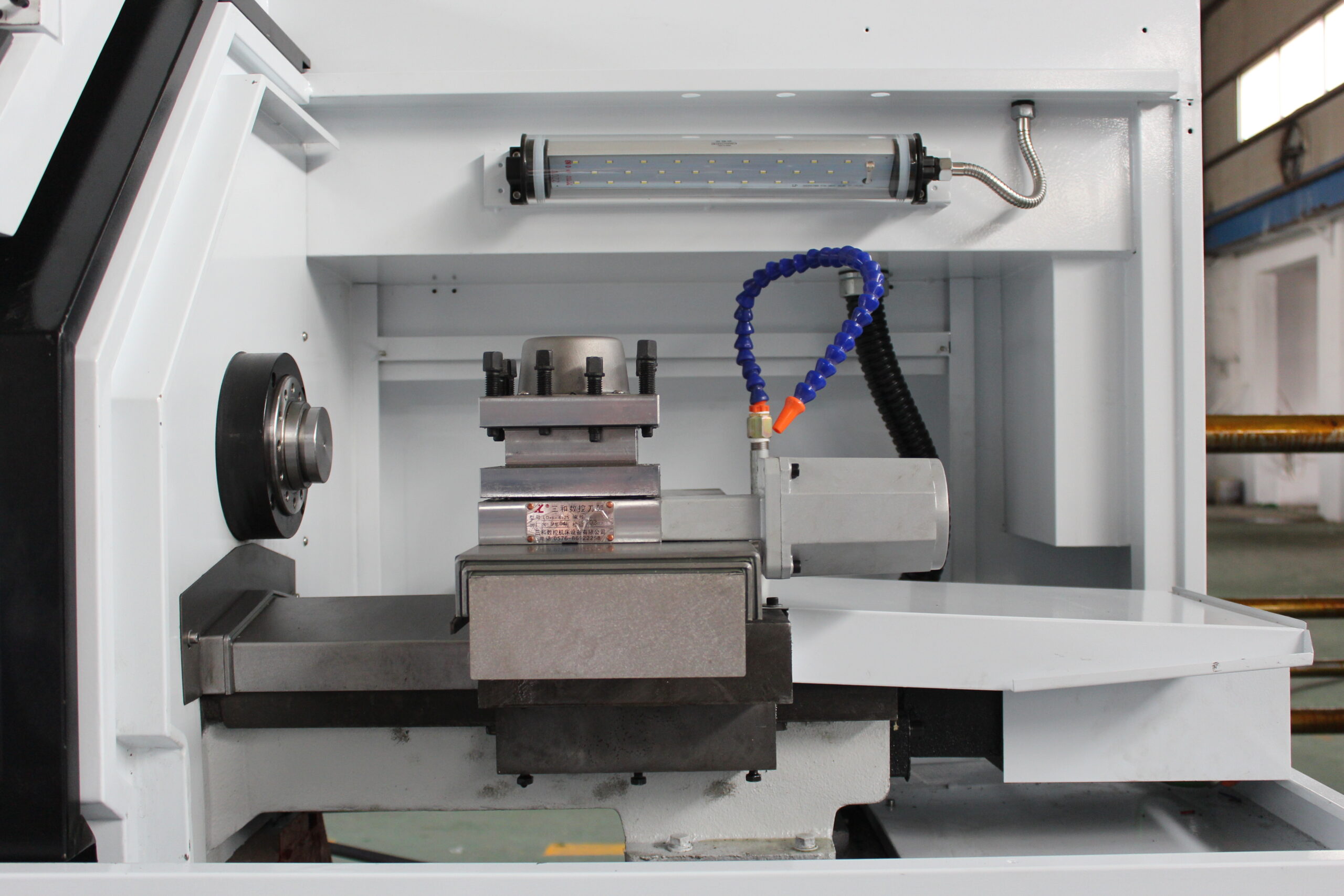

A. Bed structure: Choose a CNC lathe with a stable bed structure to ensure the stability and accuracy of the processing process.

B. Spindle power and speed: Select the appropriate spindle power and speed according to the workpiece material and processing requirements.

C. CNC system: Understand the performance and functions of the CNC system to ensure that it meets processing needs and is easy to operate and maintain.

3.

Compare different brands and models

A. Brand reputation: Choose manufacturers with good brand reputation to ensure the quality and after-sales service of CNC lathes.

B Cost-effectiveness: Compare the performance and price of different models of CNC lathes and choose products with high cost-effectiveness.

4.

Consider other factors

A. After-sales service: Understand the manufacturer’s after-sales service policy and service quality in order to obtain timely technical support and maintenance services during use.

B. Training and operation: Consider the manufacturer’s training and technical support capabilities to ensure that operators are proficient in the use and maintenance of CNC lathes.

To sum up, choosing a suitable flat bed CNC lathe requires comprehensive consideration of many factors. During the selection process, it is recommended to communicate with professional CNC lathe manufacturers or sellers to learn about product details and technical support. At the same time, you can also refer to the reviews and usage experiences of other users to make a more informed choice.